Understanding the Process: How Injection Molding Molds Shape Our Daily Products

Injection molding mold is a fundamental technology that significantly shapes the products we use in our daily lives, from simple household items to complex components in advanced machinery. This process involves creating a mold to produce parts by injecting molten material, typically plastic, into a precisely crafted cavity.

The versatility and efficiency of injection molding allow for the mass production of consistent and high-quality parts, catering to various industries, including automotive, electronics, and consumer goods. As we dive deeper into understanding the intricacies of this manufacturing process, we will explore its various stages, the materials used, and the impact it has on product design and sustainability.

The implications of injection molding mold extend beyond mere production; they influence economic factors, innovation in design, and advancements in manufacturing technology, ultimately molding the future of consumer products.

The versatility and efficiency of injection molding allow for the mass production of consistent and high-quality parts, catering to various industries, including automotive, electronics, and consumer goods. As we dive deeper into understanding the intricacies of this manufacturing process, we will explore its various stages, the materials used, and the impact it has on product design and sustainability.

The implications of injection molding mold extend beyond mere production; they influence economic factors, innovation in design, and advancements in manufacturing technology, ultimately molding the future of consumer products.

The Basics of Injection Molding: A Comprehensive Guide

Injection molding is a prevalent manufacturing process that transforms thermoplastics into functional products, and its fundamentals are critical for newcomers to the industry. This comprehensive guide introduces the essential aspects of injection molding, from machinery operation to material selection. For instance, recent advancements highlight the cost-effectiveness of 3D printed injection molds, which can replicate the performance of traditional aluminum molds at a fraction of the cost, showcasing innovation in materials and design.

Moreover, understanding the intricacies of production techniques—including new procedures for color changes in hot-runner systems—can significantly enhance operational efficiency. As advancements continue, events and webinars are invaluable resources for those entering the industry. They provide critical insights into various molding techniques and operational strategies, such as LSR molding, enabling new molders to establish their operations successfully. Staying informed on the latest technologies and methodologies ensures that manufacturers remain competitive in a rapidly evolving market.

Materials Used in Injection Molding: Choosing the Right Plastics

Injection molding is a pivotal process in manufacturing a wide array of everyday products, and selecting the right materials is crucial for ensuring both quality and performance. According to a report from the Plastics Industry Association, over 30% of all plastic products produced in the United States are made using injection molding techniques. This underscores the importance of choosing appropriate plastics that can withstand various environmental factors while maintaining structural integrity.

When it comes to the materials themselves, thermoplastics dominate the injection molding landscape. Common choices include polypropylene (PP), which accounts for approximately 26% of all thermoplastic consumption, due to its excellent chemical resistance and versatility. Specific applications may also necessitate specialized plastics like polystyrene (PS) or polycarbonate (PC), each offering unique benefits such as impact resistance or clarity. Data from Grand View Research indicates that the global market for injection molded plastics is projected to reach $500 billion by 2024, illustrating the ongoing growth and reliance on this manufacturing technique and the materials chosen to drive innovation and efficiency in production.

The Step-by-Step Injection Molding Process: From Design to Product

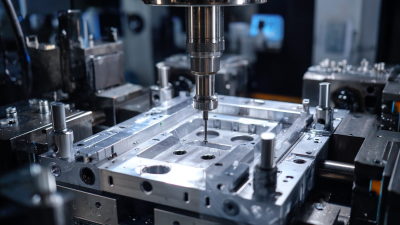

Injection molding is a sophisticated manufacturing process that plays a pivotal role in producing everyday products, from household items to automotive components. The process begins with the design phase, wherein engineers create detailed 3D models using computer-aided design (CAD) software. This stage is crucial because it sets the foundation for mold creation. According to the *2020 Global Injection Molding Market Report*, effective design can reduce cycle times by up to 30%, directly impacting production efficiency and cost-effectiveness.

Once the design is finalized, the next step involves creating the mold itself, typically made from high-grade steel or aluminum for durability. After fabrication, the mold is subjected to rigorous testing to ensure precision and quality standards. The actual injection process follows, where molten plastic is injected into the mold under high pressure. Recent industry data indicates that injection molding is capable of producing complex parts with tolerances as tight as ±0.002 inches. Finally, after cooling and solidification, products are ejected from the mold, leading to the ultimate stage: finishing and quality inspection. This step is critical, as it ensures that every item meets industry standards before reaching consumers.

Common Applications of Injection Molding in Everyday Items

Injection molding is a pivotal process in producing a wide array of everyday products, impacting various industries and daily activities. Materials like bio-polypropylene are gaining traction in this field, with the market projected to reach USD 1,160.28 million by 2029. This shift towards sustainable options reflects a growing awareness of resource conservation in product development. In fact, molded parts made from eco-friendly silicon rubber are now adhering to stringent food contact regulations, ensuring consumer safety without compromising functionality.

The plastic injection molding market is also on a significant growth trajectory, expected to rise from USD 10.50 billion in 2025 to approximately USD 13.70 billion by 2033. This robust market growth illustrates the increasing reliance on injection-molded components across various sectors, including automotive and consumer goods. Moreover, the Indian market for injection-molded plastics is anticipated to climb to USD 27.84 billion by 2024, highlighting the global demand for optimized, high-quality plastic products.

Innovations in Injection Molding Technology: The Future of Manufacturing

The injection molding industry is experiencing a transformative wave of innovation that is reshaping manufacturing processes across various sectors. According to a recent report by Technavio, the global injection molding market size is expected to grow by $56.68 billion from 2021 to 2025, accelerating at a compound annual growth rate (CAGR) of 5.5%.

This exponential growth highlights the increasing demand for efficient and cost-effective production methods, with advanced technologies playing a pivotal role.

Innovations such as 3D printing integration, robotic automation, and the utilization of smart sensors are enhancing injection molding capabilities. For instance, the introduction of AI-driven predictive maintenance allows manufacturers to reduce downtime and improve product quality. A report by Mordor Intelligence indicates that the application of AI in manufacturing is predicted to contribute up to $15.7 trillion to the global economy by 2030, underscoring the significance of technological advancements in injection molding.

These innovations not only improve production efficiency but also enable the creation of complex designs and sustainable practices, positioning injection molding at the forefront of future manufacturing trends.