Transforming Manufacturing Efficiency with Advanced Plastic Injection Machine Technology

The manufacturing landscape is undergoing a significant transformation, driven by advancements in technology and the integration of digital solutions. Central to this evolution is the development of state-of-the-art plastic injection machines, which have become pivotal in enhancing efficiency and productivity within the industry. According to a recent report by MarketsandMarkets, the global plastic injection molding market is projected to reach USD 441.2 billion by 2026, exhibiting a CAGR of 4.5% from 2021 to 2026. This growth is attributed to the increasing demand for lightweight materials and the rising adoption of automation in manufacturing processes. With innovations such as smart manufacturing techniques and connectivity through the Internet of Things (IoT), modern plastic injection machines are not only improving production speed but also minimizing waste and energy consumption. As industries strive for sustainability and cost-effectiveness, leveraging advanced plastic injection machine technology has become essential in achieving competitive advantage and operational excellence.

The Importance of Advanced Plastic Injection Machines in Modern Manufacturing

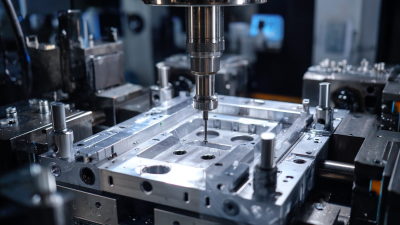

Advanced plastic injection machines play a pivotal role in modern manufacturing, enhancing both efficiency and precision in production processes. These machines are designed to optimize material use and reduce cycle times, allowing manufacturers to produce high-quality components at a faster rate. As industries strive for greater sustainability and productivity, the integration of advanced injection molding technology becomes crucial. By leveraging innovative features such as automation and real-time monitoring, companies can significantly streamline their operations, resulting in lower production costs and improved output quality.

Tips for manufacturers looking to invest in advanced plastic injection machines include evaluating the specific needs of their production line to ensure they choose a machine that fits their operational requirements. Additionally, consider the importance of energy efficiency; selecting machines that consume less power can lead to substantial savings over time. Finally, prioritize machines with robust support and maintenance services, as this can greatly enhance their longevity and performance, enabling seamless manufacturing processes.

Impact of Advanced Plastic Injection Machines on Manufacturing Efficiency

This chart illustrates the increasing efficiency in manufacturing processes attributed to the use of advanced plastic injection machines over recent years. The data compares production volume (in units) and defect rate (in percentage) across three years, showcasing the positive impact of adopting advanced technologies.

Key Features That Enhance Efficiency in Injection Molding Processes

The manufacturing industry has witnessed a significant transformation with the advent of advanced plastic injection machine technology. Key features of these machines play a pivotal role in enhancing efficiency within injection molding processes. For instance, the integration of automation and IoT capabilities allows for real-time monitoring and data analytics, leading to reduced cycle times and improved quality control. According to a report by MarketsandMarkets, the global injection molding machine market is expected to grow from $16.02 billion in 2020 to $22.65 billion by 2025, driven by the demand for high-precision manufacturing.

Advanced plastic injection machines also boast enhanced energy efficiency, which is crucial for reducing operational costs. Features such as servo motors and energy-saving modes can help reduce energy consumption by 30-50%, according to industry data. Furthermore, the capability for rapid mold changeovers minimizes downtime, translating to increased production capacity. Beyond machinery, implementing smart scheduling systems can further streamline workflows and improve output.

Tip: Regular maintenance and updates to the machines’ software can significantly enhance performance. Staying ahead with the latest technology trends, including machine learning algorithms, can provide insights that optimize production processes even further. Always consider training staff on new systems to ensure maximum efficiency and productivity within your operations.

How Automation and Technology Integration Boost Productivity in Manufacturing

The integration of automation and technology within manufacturing processes has revolutionized the plastic injection molding industry. Advanced plastic injection machines are now equipped with smart technology, enabling real-time monitoring and adjustments. This not only minimizes human error but also enhances the precision of each injection cycle. As a result, manufacturers can achieve consistent quality in their products, which is essential in a competitive market. With automated systems handling repetitive tasks, skilled labor can be redirected towards more complex operations, effectively increasing overall productivity.

Moreover, the use of data analytics in conjunction with these advanced machines allows for predictive maintenance and process optimization. Manufacturers can gather valuable insights on machine performance, identifying potential issues before they lead to costly downtimes. This proactive approach ensures that production schedules are met without interruptions. Additionally, the seamless integration of cutting-edge technologies like AI and IoT further amplifies efficiency, leading to shorter production times and reduced waste. The synergy of these advancements signifies a new era in manufacturing, where automation not only boosts output but also drives innovation across the sector.

Cost Savings and Waste Reduction Through Advanced Injection Machine Technology

The integration of advanced plastic injection machine technology has revolutionized manufacturing processes, particularly through its significant contributions to cost savings and waste reduction. By employing state-of-the-art machinery, companies are able to streamline their production lines, effectively lowering operational costs. These machines are designed with precision and efficiency in mind, ensuring that materials are utilized to their fullest potential. The reduction in scrap waste not only leads to lower material costs but also enhances overall productivity, allowing manufacturers to increase output without the need for extensive additional resources.

Furthermore, advanced injection molding technology employs sophisticated software and real-time monitoring systems that optimize the injection process. This real-time data analysis helps identify and rectify production inefficiencies instantaneously, preventing costly downtime and material wastage. As a result, manufacturers can achieve a more sustainable operation, reducing their environmental footprint while maintaining high levels of productivity. By investing in these cutting-edge machines, businesses are not just saving money but also positioning themselves for long-term success in an increasingly competitive landscape.

Transforming Manufacturing Efficiency with Advanced Plastic Injection Machine Technology

| Parameter | Before Implementation | After Implementation | Percentage Change |

|---|---|---|---|

| Cycle Time (seconds) | 25 | 20 | -20% |

| Material Waste (kg) | 15 | 5 | -66.67% |

| Energy Consumption (kWh) | 300 | 240 | -20% |

| Production Rate (units/hour) | 100 | 120 | 20% |

| Cost Per Unit ($) | 2.50 | 2.00 | -20% |

Future Trends in Plastic Injection Machines and Their Impact on Manufacturing Efficiency

The plastic injection machine market is on the brink of significant transformation, driven by advanced technologies and innovative manufacturing processes. In particular, the LIM (Liquid Injection Molding) and LSR (Liquid Silicone Rubber) injection machine segments are projected to see remarkable growth, with market valuations expected to rise from $159.5 million in 2024 to $283.83 million by 2032. This 7.47% annual growth rate highlights the increasing demand for efficiency and precision in manufacturing applications.

As industries embrace these advancements, plastic injection machines are becoming crucial in enhancing production capabilities. Future trends indicate a shift towards more automated solutions, integrating smart technologies like AI and IoT to optimize processes. This not only reduces waste but also increases flexibility in manufacturing, enabling companies to adapt to changing market demands swiftly. The impact of such innovations on manufacturing efficiency is profound, positioning businesses to meet the challenges of the modern economy while maintaining a competitive edge.

Related Posts

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products

-

Exploring the Future of Union Tool: Innovations and Applications in Today’s Industry

-

Exploring Innovations in Plastic Manufacturing: Sustainable Solutions for Tomorrow

-

The Ultimate Guide to Choosing the Best Union Tool for Your Project

-

Innovative Molding Tools for Streamlined Manufacturing Processes

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency