Top 10 Plastic Mold Injection Machines to Watch in 2025

In the rapidly evolving landscape of manufacturing, the significance of plastic mold injection machines cannot be overstated. As one of the most vital components in producing a wide array of plastic products, these machines have seen substantial technological advancements and innovations. The market for plastic mold injection machines is projected to grow significantly in the coming years, driven by increased demand for high-quality and efficient production processes across various industries, including automotive, consumer goods, and medical applications.

Looking towards 2025, it is essential for manufacturers and stakeholders to stay informed about the latest trends and developments within this domain. Understanding the capabilities of modern plastic mold injection machines, as well as their potential impact on production efficiency and sustainability, is crucial for strategic decision-making. This article will explore the top 10 plastic mold injection machines to watch in 2025, highlighting key features and trends that will shape the future of this indispensable technology. As the industry continues to innovate, identifying these influential machines will provide valuable insights for optimizing manufacturing processes and achieving a competitive edge in the marketplace.

Overview of Plastic Mold Injection Machines

Plastic mold injection machines play a pivotal role in modern manufacturing, particularly in the production of plastic components across various industries, including automotive, consumer goods, and packaging. The global market for injection molding machines is expected to reach approximately $12 billion by 2025, with a compound annual growth rate (CAGR) of around 5% from 2020 to 2025. This growth can be attributed to advancements in technology, as manufacturers seek more efficient and versatile machines capable of meeting the demands of high-speed production and precision molding.

One significant trend in the industry is the increase in automation within plastic mold injection processes. According to a recent industry report, over 60% of manufacturers are adopting fully automated solutions to enhance productivity and reduce labor costs. Electric injection molding machines are gaining traction for their energy efficiency, precision, and lower maintenance costs, projected to capture 30% of the market share by 2025. As sustainability becomes a crucial focus, machine builders are also innovating to create machines that minimize material waste and energy consumption, aligning with global environmental standards. This shift is not only beneficial for manufacturers but also supports efforts to reduce the environmental impact of plastic production.

Key Trends in Plastic Injection Molding for 2025

As we approach 2025, the landscape of plastic injection molding is set to evolve dramatically, driven by technological advancements and increasing sustainability demands. One of the key trends is the rise of automation in the molding process. The integration of robotics and smart technologies not only enhances production efficiency but also improves quality control by minimizing human error and ensuring more consistent product outcomes. This shift towards automation is complemented by the use of data analytics, allowing manufacturers to monitor and optimize processes in real-time, ultimately leading to reduced downtime and increased throughput.

Another significant trend is the emphasis on sustainable practices within the plastic injection molding industry. Companies are increasingly seeking eco-friendly materials and processes that align with global sustainability goals. Innovations such as biodegradable plastics and energy-efficient machines are gaining traction, as they help reduce the environmental impact of production. Furthermore, recycling technologies are becoming more sophisticated, enabling manufacturers to reclaim and reuse materials more effectively, which not only lowers costs but also supports circular economy principles. As these trends shape the future of plastic injection molding, the industry is poised for significant transformations that will enhance both productivity and environmental stewardship in the coming years.

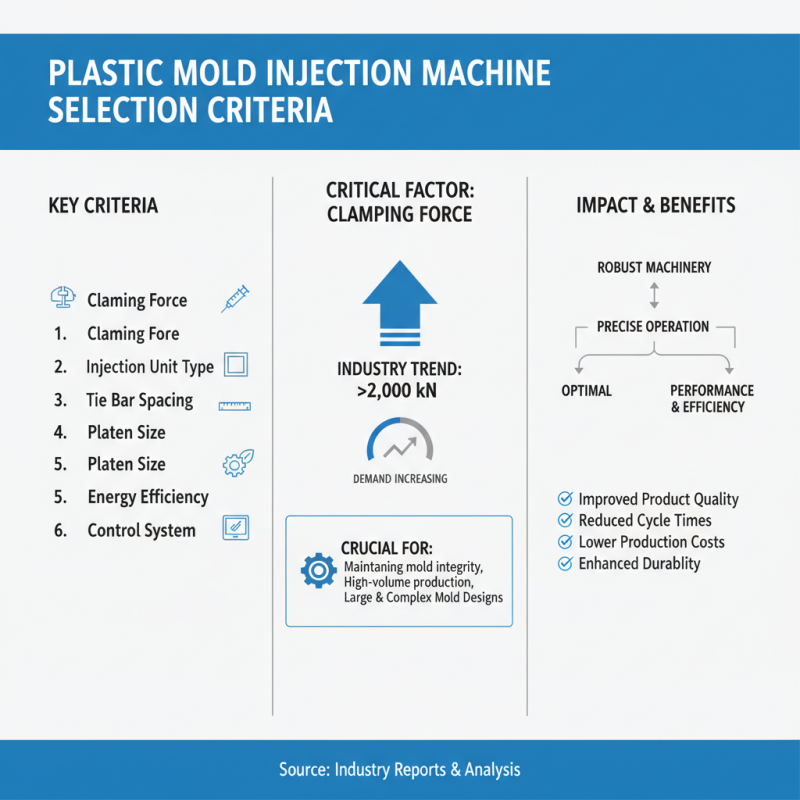

Criteria for Selecting the Best Injection Machines

When selecting the best plastic mold injection machines, several critical criteria must be considered to ensure optimal performance and efficiency. One of the primary factors is the machine's clamping force, which is crucial for maintaining mold integrity during the injection process. According to industry reports, the demand for machines with clamping forces exceeding 2,000 kN is growing, particularly in high-volume production scenarios. This increase is indicative of the industry's shift towards larger and more complex mold designs that require robust machinery for precise operation.

Another essential criterion is the automation capabilities of the injection machines. A recent market analysis highlights that advanced automation features, such as robotics integration and smart connectivity, can enhance production efficiency by up to 30%. These technologies enable real-time monitoring and adjustments during the injection process, ultimately reducing cycle times and waste. Moreover, energy efficiency is also a critical factor, with machines utilizing servo technology reported to consume up to 50% less energy compared to traditional hydraulic systems. This not only lowers operational costs but also aligns with the industry's increasing focus on sustainability. By prioritizing these criteria, manufacturers can ensure they select injection machines that meet current and future production needs.

Top 10 Plastic Mold Injection Machines to Monitor

As we look towards 2025, the plastic mold injection machine market is set to experience significant transformations that manufacturers and industry professionals should closely monitor. With advancements in technology and a growing emphasis on efficiency and sustainability, the landscape of injection molding is evolving. Trends indicate a rise in machines that incorporate smart technology, enabling enhanced precision and real-time data analysis for improved production workflows.

Additionally, the demand for energy-efficient and environmentally friendly machines is likely to shape purchasing decisions. Manufacturers are increasingly focused on reducing their carbon footprint and improving overall sustainability in their processes. Machines that offer lower energy consumption without compromising on performance will be in high demand. Furthermore, innovations such as automation and robotic integration will streamline operations, making it essential for industry players to pay attention to these developments.

In conclusion, 2025 will be a pivotal year for plastic mold injection machines. Staying abreast of the latest technologies and sustainability trends will allow businesses to remain competitive in a rapidly changing market. The focus on smart manufacturing solutions and eco-friendly operations will be crucial as companies strive to meet both consumer demands and regulatory requirements.

Top 10 Plastic Mold Injection Machines to Watch in 2025

| Model | Clamping Force (ton) | Injection Volume (cm³) | Cycle Time (s) | Control Type | Price Range (USD) |

|---|---|---|---|---|---|

| Model A | 150 | 160 | 15 | Electric | $40,000 - $50,000 |

| Model B | 180 | 200 | 12 | Hydraulic | $35,000 - $45,000 |

| Model C | 200 | 250 | 10 | Hybrid | $50,000 - $60,000 |

| Model D | 120 | 130 | 18 | Electric | $30,000 - $40,000 |

| Model E | 160 | 180 | 14 | Hydraulic | $38,000 - $48,000 |

| Model F | 220 | 300 | 9 | Hybrid | $55,000 - $65,000 |

| Model G | 250 | 350 | 8 | Electric | $60,000 - $70,000 |

| Model H | 130 | 110 | 20 | Hydraulic | $28,000 - $38,000 |

| Model I | 170 | 190 | 13 | Hybrid | $45,000 - $55,000 |

| Model J | 190 | 220 | 11 | Electric | $50,000 - $60,000 |

Future Innovations and Technologies in Injection Molding

As we look towards 2025, the realm of injection molding is poised for significant advancements, driven by the desire for greater efficiency, precision, and sustainability. Innovations in machine technology will likely focus on integrating smart manufacturing and Industry 4.0 principles. This means more machines equipped with sensors and IoT capabilities that provide real-time data analytics, enabling manufacturers to optimize processes, reduce waste, and enhance product quality. The convergence of artificial intelligence with injection molding could also revolutionize the way machines learn and adapt to production needs, resulting in shorter cycle times and improved operational reliability.

Tips: When considering new injection molding technologies, focus on energy efficiency and material conservation. Investing in machines that employ advanced cooling techniques or low-energy consumption modes can lead to a more sustainable production process. Additionally, stay informed about materials innovation, particularly bioplastics, which are becoming increasingly viable in the industry.

The future of injection molding also includes the rise of additive manufacturing techniques. Hybrid models that integrate traditional injection molding with 3D printing capabilities are gaining traction, presenting opportunities for customization and faster prototyping. This could significantly reduce lead times and enable manufacturers to respond swiftly to market demands. As innovations continue to emerge, staying ahead in the industry will require continuous learning and adaptation to embrace these new technologies effectively.

Top 10 Plastic Mold Injection Machines to Watch in 2025

Related Posts

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners

-

Exploring the Future of Union Tool: Innovations and Applications in Today’s Industry

-

Exploring Innovative Molding Solutions: Transforming Ideas into Reality Through Advanced Techniques

-

How Injection Mold Manufacturing is Revolutionizing Product Development in 2023

-

Top Strategies for Design for Manufacturing to Enhance Production Efficiency

-

2025 Top 5 Innovative Prototype Molds Transforming Product Development