Top 10 Plastic Mold Injection Machine Solutions for Your Manufacturing Needs

In the fast-evolving world of manufacturing, the choice of equipment plays a crucial role in the efficiency and quality of production processes. Among the various tools available, the plastic mold injection machine stands out as a fundamental piece of technology that has transformed the industry. Renowned industry expert Dr. Helen Archer, a leading engineer in advanced manufacturing techniques, aptly states, "Investing in the right plastic mold injection machine is not just about production; it’s about optimizing quality and reducing costs in the long run."

As manufacturers aim to enhance their operations and meet the growing demands of consumers, selecting the appropriate plastic mold injection machine becomes increasingly critical. This guide delves into the top ten solutions available in the market, offering insights into features, capabilities, and applications that cater to diverse manufacturing needs.

In today’s competitive landscape, leveraging the advancements in plastic mold injection technology can provide companies with the edge they need to thrive. From precision molding to energy efficiency, these machines are instrumental in producing high-quality products that stand the test of time. We present an overview that not only highlights these top solutions but also equips manufacturers with the knowledge necessary to make informed decisions in their investment strategies.

Top Considerations for Selecting Injection Molding Machines in 2023

When selecting injection molding machines in 2023, manufacturers must consider several key factors to ensure optimal performance and efficiency. According to a recent report by Grand View Research, the global injection molding machine market is projected to reach USD 21.31 billion by 2027, growing at a CAGR of 4.8%. This growth emphasizes the importance of investing in high-quality machinery tailored to specific manufacturing needs.

One crucial consideration is the machine's clamping force, which affects the quality and consistency of molded products. Top manufacturers recommend a clamping force that matches the material requirements and part design. Additionally, energy efficiency is becoming increasingly important, as machines that utilize hydraulic and electric technologies can significantly reduce operational costs.

**Tips:** Prioritize machines with advanced control systems that allow for precise adjustments during production. Furthermore, consider the availability of local technical support and spare parts, which can minimize downtime and maintain production efficiency. Lastly, assess the machine’s adaptability for various materials and part sizes to ensure versatility in your manufacturing processes.

Top 10 Plastic Mold Injection Machine Solutions for Your Manufacturing Needs

| Model | Clamping Force (ton) | Injection Volume (cm³) | Cycle Time (s) | Energy Efficiency Rating |

|---|---|---|---|---|

| Model A | 150 | 120 | 30 | A+ |

| Model B | 200 | 150 | 28 | A |

| Model C | 120 | 100 | 35 | B+ |

| Model D | 250 | 180 | 27 | A++ |

| Model E | 300 | 220 | 25 | A++ |

| Model F | 50 | 80 | 40 | B |

| Model G | 125 | 110 | 32 | A |

| Model H | 175 | 140 | 29 | A+ |

| Model I | 400 | 300 | 22 | A++ |

| Model J | 175 | 130 | 30 | B+ |

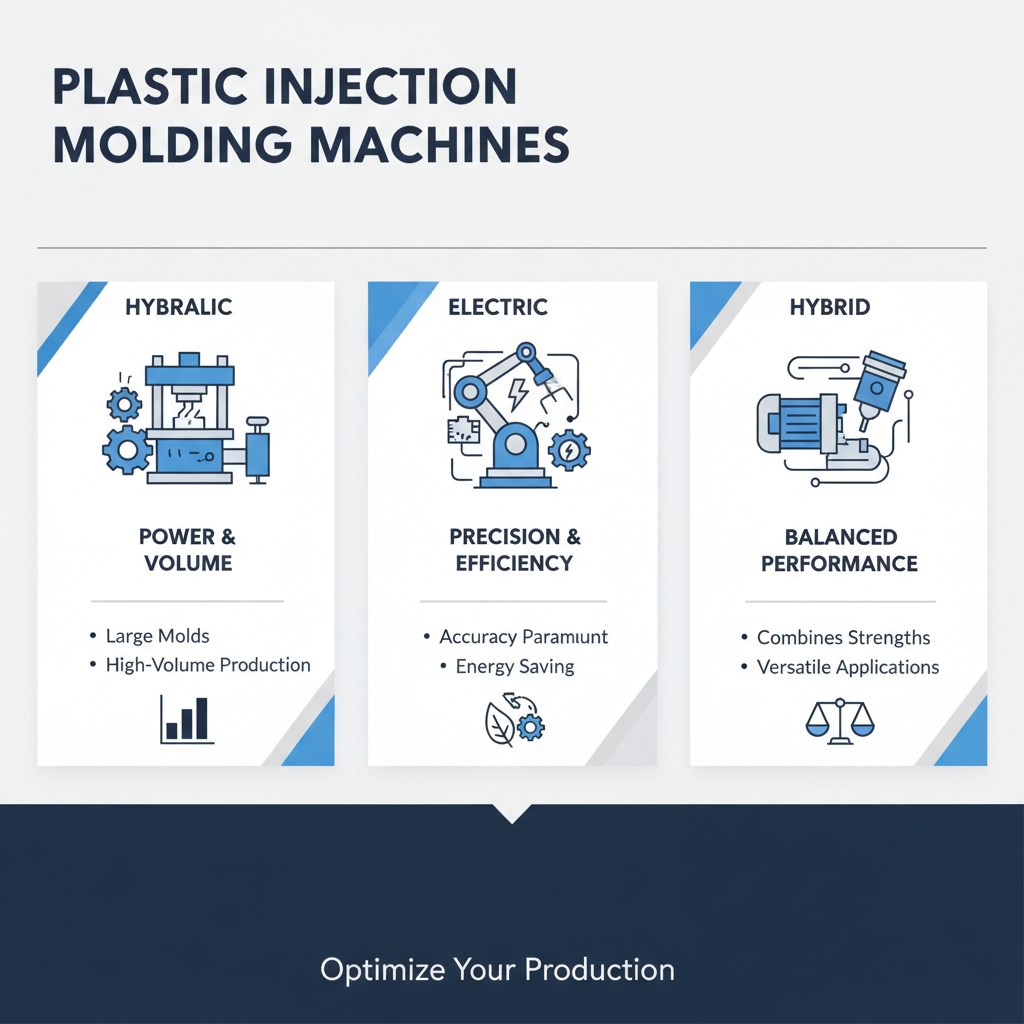

Understanding Different Types of Plastic Injection Molding Machines

In the realm of manufacturing, understanding the various types of plastic injection molding machines is crucial for optimizing production processes. These machines are typically categorized based on application, design, and operation. The primary types include hydraulic, electric, and hybrid injection molding machines. Hydraulic machines are renowned for their power and ability to handle larger molds, making them a popular choice in high-volume production scenarios. Conversely, electric machines offer precision and energy efficiency, thus becoming increasingly favored in industries where accuracy is paramount.

Moreover, the evolving landscape of the plastic injection molding market is closely tied to technological advancements. The global micro injection molding machine segment is particularly noteworthy, projected to grow from $551.3 million in 2025 to $759.2 million by 2032, highlighting a robust market trend. This growth underscores the importance of selecting the right machine type tailored to specific manufacturing needs, from micro applications in electronics to more extensive, heavy-duty operations in automotive manufacturing. As companies assess their machinery options, understanding these types and advancements can lead to more informed investment decisions and enhanced production efficiency.

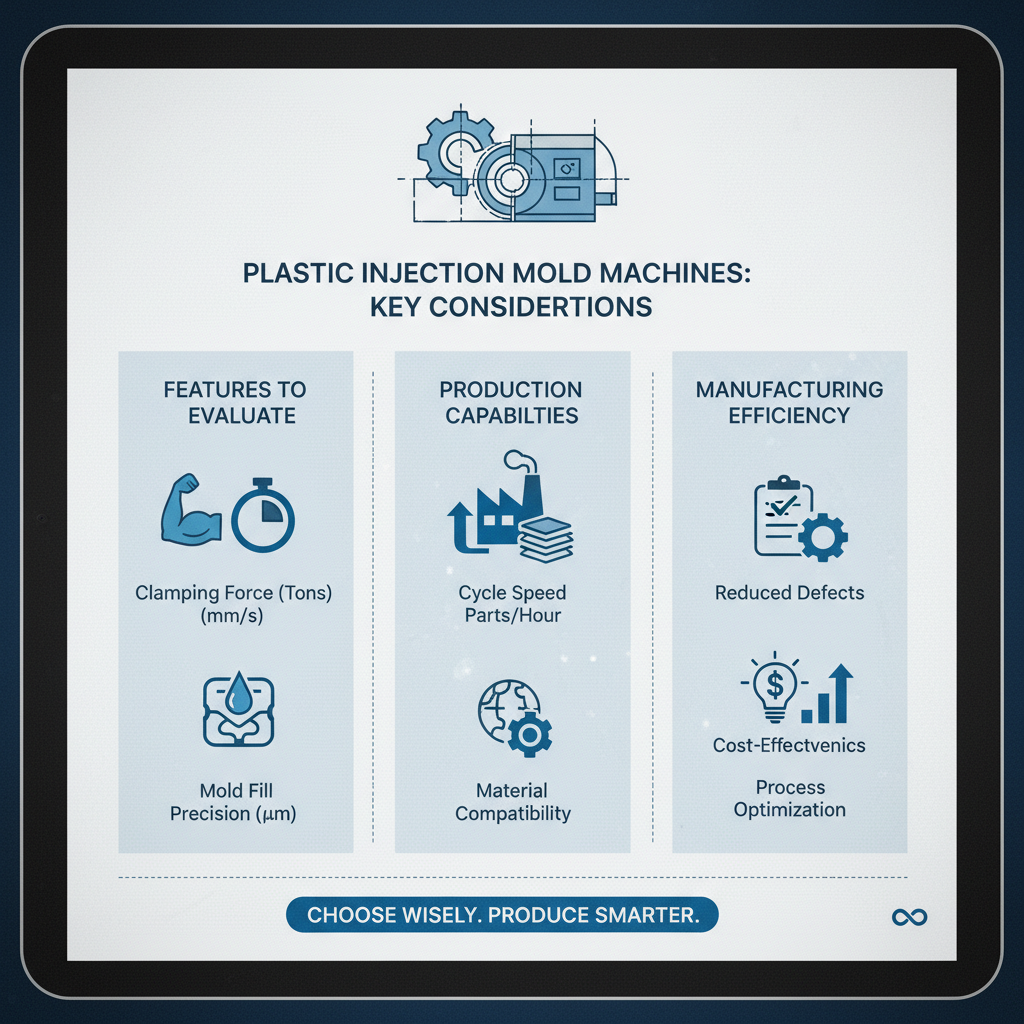

Comparative Analysis of Machine Features and Production Capabilities

When considering options for plastic mold injection machines, it’s essential to conduct a comparative analysis of their features and production capabilities. The efficiency of any manufacturing process often hinges on understanding how different machines can meet specific needs. Key features to evaluate may include clamping force, injection speed, and precision of mold fill, as these attributes directly influence the quality and speed of production cycles.

Furthermore, advancements in machine learning can provide valuable insights when assessing these machines. For instance, analyzing sensor data from various injection molding systems can help identify performance trends and predict maintenance needs. By leveraging predictive maintenance models, manufacturers can reduce downtime and enhance operational efficiency. This holistic approach not only aids in selecting the right machine but also ensures that production lines are optimized for both current demands and future scalability.

Key Industry Trends Impacting Injection Molding Technology

The injection molding industry is experiencing significant shifts driven by technological advancements and changing market demands. According to a market report, the global injection molding market revenue was valued at approximately USD 10.50 billion in 2025, projected to reach around USD 13.70 billion by 2033. This growth reflects a robust compound annual growth rate (CAGR) of about 5.4%, showcasing the increasing reliance on injection molding processes across various sectors, including automotive, consumer goods, and packaging.

Furthermore, the emergence of micro injection molding machines illustrates the market's evolution towards precision manufacturing. The micro injection molding machine market is anticipated to grow from $551.3 million in 2025 to $759.2 million by 2032, depicting a CAGR of 4.7%. This trend is primarily driven by the rising demand for compact and high-precision components, especially in the medical device industry. As manufacturers seek to innovate and optimize production efficiency, understanding these industry trends is crucial for leveraging the right plastic mold injection machine solutions that cater to specific manufacturing needs.

Top 10 Plastic Mold Injection Machine Solutions for Your Manufacturing Needs

The following chart illustrates the average production efficiency and cycle time of the top 10 plastic mold injection machine solutions, highlighting key trends in injection molding technology.

Evaluating Cost Efficiency and ROI of Injection Molding Solutions

When evaluating injection molding machines for cost efficiency and return on investment (ROI), it's essential to consider not only the initial capital outlay but also the long-term operational costs. According to a report from Allied Market Research, the global injection molding machine market is expected to reach $26.4 billion by 2027, highlighting the growing demand for efficient manufacturing solutions. A key factor in achieving a positive ROI is the machine's ability to minimize scrap rates and energy consumption. Companies can save up to 30% on energy costs with the latest electric injection molding machines compared to traditional hydraulic models.

Tips: Always conduct a thorough analysis of the total cost of ownership (TCO) for the machines you're considering. This should include maintenance costs, energy usage, and potential scrap losses to ensure you're making an informed decision.

Additionally, factoring in production cycle times can significantly impact ROI. A study from Mordor Intelligence shows that optimizing cycle times by as little as 10% can lead to a 20-30% increase in productivity. Therefore, investing in machines that provide advanced automation and real-time monitoring can enhance production efficiency and ultimately improve your bottom line.

Tips: Look for machines that offer precision and speed while maintaining reliability. Investing in higher quality equipment upfront can translate to lower operational costs and higher profitability over time.

Related Posts

-

What is Plastic Mold Injection Machine? A Comprehensive Guide to Its Types and Applications

-

Transforming Manufacturing Efficiency with Advanced Plastic Injection Machine Technology

-

2025 Top Plastic Injection Molded Parts: Innovations and Market Trends

-

Discover the Best Union Tool Products: 2025 Top Digital Types You Need

-

Exploring Innovative Molding Solutions: Transforming Ideas into Reality Through Advanced Techniques

-

2025 Top 5 Innovative Prototype Molds Transforming Product Development