Top 10 Plastic Injection Molded Parts You Need to Know for Your Business

In the realm of manufacturing, understanding the significance of "plastic injection molded parts" is crucial for any business seeking efficiency and innovation. Renowned expert Dr. John Smith, a leading authority in the field of plastics engineering, once stated, "The future of manufacturing lies in the seamless integration of design and technology, particularly through the use of plastic injection molded parts." This insight highlights not only the technological advancements within the industry but also the versatility and cost-effectiveness that these parts offer.

As businesses strive to enhance their production capabilities, the role of plastic injection molded parts becomes increasingly prominent. These components are integral to various industries, from automotive to consumer goods, as they offer precision, durability, and the potential for mass production. Understanding the top ten essential plastic injection molded parts is vital for entrepreneurs and manufacturers alike, as it empowers them to make informed decisions, streamline operations, and ultimately drive growth. In this article, we will explore these pivotal components and their impact on contemporary manufacturing practices.

Essential Overview of Plastic Injection Molding in Manufacturing

Plastic injection molding is a cornerstone of modern manufacturing, widely utilized due to its efficiency and versatility in producing complex parts across various industries. According to recent industry reports, the global plastic injection molding market is projected to reach approximately $400 billion by 2027, driven by increased demand in automotive, consumer goods, and medical applications. This method allows for the rapid production of high-quality parts with consistent accuracy, minimizing waste and material costs.

In the realm of plastic injection molded parts, understanding the nuances of the process is crucial for businesses aiming to optimize production. The ability to create intricate designs with tight tolerances significantly impacts product performance. Industry data suggests that nearly 30% of the total manufacturing cost can be attributed to the design and production phases, emphasizing the importance of selecting the right materials and processes. Furthermore, advancements in technology, such as the adoption of robotics and automation in mold handling, are enhancing production efficiency, reducing cycle times, and improving overall output. Understanding these dynamics is essential for any business looking to leverage plastic injection molding effectively.

Top 10 Plastic Injection Molded Parts You Need to Know for Your Business

This chart illustrates the production volume of the top 10 plastic injection molded parts essential for businesses. Understanding these parts and their manufacturing volumes can help in planning and optimizing production processes.

Common Applications of Injection Molded Parts Across Industries

Injection molded parts play a critical role in various industries, from automotive to consumer goods. According to the Global Injection Molded Plastics Market report, the market was valued at approximately $317 billion in 2020 and is projected to reach around $584 billion by 2026, reflecting robust growth due to the increasing demand for lightweight, durable components. These parts are not only efficient to produce but also offer flexibility in design and material choice, making them indispensable in sectors such as healthcare, electronics, and construction.

The automotive industry is one of the largest consumers of injection molded parts, utilizing them for components like dashboards, bumpers, and interior fixtures. In healthcare, these parts are used for items such as syringes, medical devices, and lab equipment due to their hygienic and customizable nature. Additionally, consumer electronics rely on injection molded parts for housings and connectors, ensuring both performance and aesthetic appeal.

Tips: When considering injection molding for your business, focus on material selection to enhance product durability and reduce costs. Additionally, collaborating with experienced mold makers can lead to significant efficiency improvements. Keeping up-to-date with industry trends will ensure your product remains competitive in a rapidly evolving marketplace.

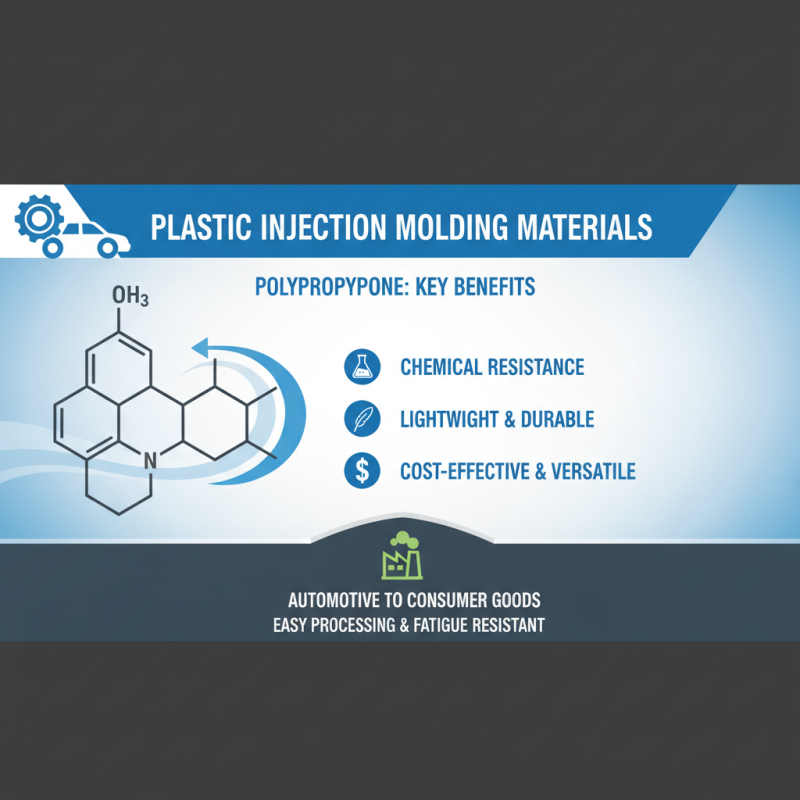

Key Materials Used in Plastic Injection Molded Parts Production

When it comes to producing plastic injection molded parts, the choice of materials is crucial for achieving the desired performance and durability. One of the most commonly used materials is polypropylene, known for its excellent chemical resistance and lightweight properties. This thermoplastic is not only versatile but also cost-effective, making it ideal for various applications, from automotive components to consumer goods. Its ability to withstand fatigue and its ease of processing further enhance its popularity in the industry.

Another key material is ABS (Acrylonitrile Butadiene Styrene), prized for its impact resistance and surface finish. ABS is often selected for products requiring a robust feel and durability, such as household items and electronic housings. Additionally, polycarbonate is recognized for its strength and transparency, making it a go-to choice in industries where visibility and resilience are paramount, like lenses and safety equipment. Each of these materials presents unique advantages, enabling businesses to select the most suitable option based on their specific requirements and production processes.

Factors Affecting the Quality of Injection Molded Products

The quality of injection molded products is influenced by several key factors that every business should consider. One of the most critical aspects is the material selection. Different polymers have varying properties that can affect the final product's strength, flexibility, and durability. It's essential to choose a material that aligns with the intended use of the product, ensuring that it meets performance criteria while also being cost-effective.

Another factor is the design of the mold itself. An intricate design can enhance the aesthetic appeal and functionality of the final product, but it requires precise engineering. The cooling time during the injection process also plays a pivotal role—too fast can lead to defects, while too slow can prolong production times.

**Tips:** To improve the quality of your injection molded parts, always conduct thorough testing with prototype molds before full-scale production. This allows you to identify potential issues without incurring significant costs. Additionally, regularly maintain your injection molding machines to ensure consistent performance and minimize defects in every batch produced. Lastly, involve your team in continuous training on the latest techniques and technologies in injection molding, which can lead to high-quality outputs and reduced production errors.

Top 10 Plastic Injection Molded Parts You Need to Know for Your Business - Factors Affecting the Quality of Injection Molded Products

| Part Name | Material Used | Typical Applications | Factors Affecting Quality |

|---|---|---|---|

| Automotive Dashboards | ABS (Acrylonitrile Butadiene Styrene) | Vehicles, Automotive Interiors | Temperature control, Mold design |

| Packaging Containers | PET (Polyethylene Terephthalate) | Food and Beverage, Cosmetics | Material purity, Cycle time |

| Home Appliance Parts | PP (Polypropylene) | Refrigerators, Ovens | Injection pressure, Mold wear |

| Medical Devices | PC (Polycarbonate) | Syringes, Surgical Tools | Surface finish, Dimensional accuracy |

| Electronic Housings | ABS, PC/ABS Blend | Telecommunications, Consumer Electronics | Moisture content, Injection speed |

| Toys | PVC (Polyvinyl Chloride) | Children's Toys, Decorative Items | Color uniformity, Cooling time |

| Industrial Components | PA (Nylon) | Machinery Parts, Gears | Heat treatment, Material flow |

| Furniture Components | Plywood-like Plastics | Chairs, Tables | Surface defects, Tension in plastic |

| Personal Care Products | HDPE (High-Density Polyethylene) | Bottles, Caps | Contamination levels, Molding speed |

| Connectors | PBT (Polybutylene Terephthalate) | Electrical Appliances, Electronics | Electrical properties, Mold temperature |

Future Trends and Innovations in Plastic Injection Molding Technology

As the plastic injection molding industry continues to evolve, businesses must stay abreast of emerging trends and innovations that can enhance efficiency and product quality. A significant trend shaping the future is the adoption of automation and robotics. According to recent industry reports, automated machines can increase production speeds by up to 50%, reduce labor costs, and improve safety in the workplace. This shift towards smart manufacturing also allows for real-time monitoring and maintenance of machinery, leading to minimized downtime and optimized operational performance.

Another area of innovation lies in the development of advanced materials. The incorporation of sustainable and biodegradable plastics is gaining traction, with studies indicating that the market for biodegradable plastics is projected to reach $6.7 billion by 2024. Businesses that pivot towards these eco-friendly alternatives not only meet consumer demands for sustainability but also position themselves favorably in an increasingly environmentally-conscious market.

Tip: Regularly evaluate your current materials and production processes to identify potential areas for sustainability improvements, which can ultimately enhance your brand's reputation and attract new customers.

Moreover, advancements in additive manufacturing and 3D printing technologies are set to revolutionize the prototyping phase in plastic injection molding. With the capability to create complex designs in a fraction of the time, companies can achieve faster turnaround times for product development. This can lead to shorter time-to-market periods, which is crucial in today's competitive landscape.

Tip: Investing in training for your team on the latest 3D printing techniques can empower them to innovate and streamline the design process, fostering a culture of creativity and efficiency.

Related Posts

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency

-

Exploring Innovations in Plastic Manufacturing: Sustainable Solutions for Tomorrow

-

How Injection Mold Manufacturing is Revolutionizing Product Development in 2023

-

2025 Top Plastic Injection Molded Parts: Innovations and Market Trends

-

How to Optimize Injection Mold Design for Better Production Efficiency

-

The Ultimate Guide to Choosing the Best Union Tool for Your Project