Top Mold Injection Techniques for Efficient Manufacturing in 2025

The realm of manufacturing is continuously evolving, driven by advancements in technology and changing market demands. Among the various production techniques, mold injection stands out as a pivotal process that significantly enhances efficiency and cost-effectiveness. According to a recent report by MarketsandMarkets, the global mold injection market is projected to reach $25 billion by 2025, highlighting its growing importance in sectors such as automotive, consumer goods, and electronics. This surge can be attributed to the method's ability to produce complex geometries and high-quality parts with minimal waste.

As manufacturers strive for greater sustainability and competitiveness, the optimization of mold injection techniques will be crucial. The integration of industry 4.0 technologies, including artificial intelligence and IoT, is expected to revolutionize mold injection processes, enabling real-time monitoring and predictive maintenance. Furthermore, research from the International Journal of Advanced Manufacturing Technology indicates that adopting advanced mold designs and materials can enhance production speed by up to 30%, appealing to an increasingly efficiency-driven market.

In this context, the exploration of top mold injection techniques for efficient manufacturing in 2025 becomes not only timely but essential. This article will delve into innovative strategies that businesses can implement to stay ahead of the curve, harness the full potential of mold injection, and respond to the burgeoning demands of a dynamic global marketplace.

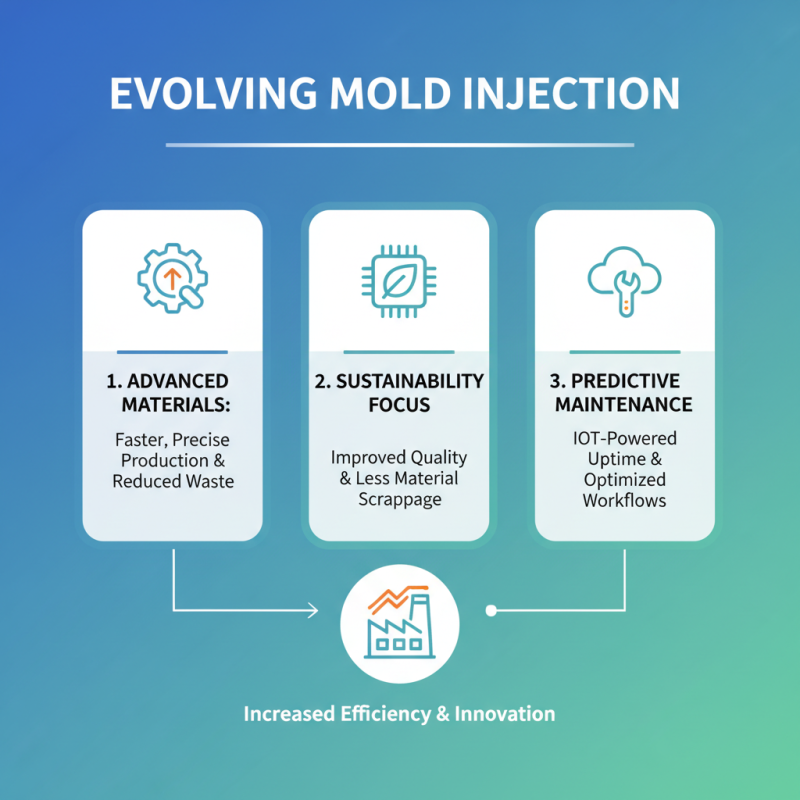

Top Mold Injection Techniques: An Overview of Current Innovations

The world of mold injection is rapidly evolving, driven by innovations that enhance efficiency and sustainability. One of the most significant trends is the integration of advanced materials that allow for faster and more precise production processes. These materials not only improve the quality of the final products but also reduce waste during manufacturing. Additionally, the use of predictive maintenance powered by IoT technology has emerged, enabling manufacturers to anticipate equipment failures and reduce downtime, thereby streamlining production workflows.

Another notable innovation is the adoption of hybrid injection molding techniques, which combine traditional methods with advanced technologies such as 3D printing. This approach not only accelerates prototyping but also allows for greater flexibility in design changes, catering to the increasingly diverse needs of industries. Furthermore, automation and robotics play a critical role in enhancing productivity by minimizing human intervention and maximizing precision. As these techniques continue to evolve, manufacturers are poised to significantly increase their output while maintaining high standards of quality and efficiency, ultimately shaping the future of manufacturing in 2025 and beyond.

Key Benefits of Injection Molding in the 2025 Manufacturing Landscape

In the evolving landscape of manufacturing in 2025, injection molding has emerged as a pivotal technique that offers numerous advantages. One of the primary benefits is precision. Modern injection molding technology allows for the production of complex shapes with remarkable accuracy, thereby reducing the need for extensive post-processing. This precision not only enhances product quality but also minimizes waste, making it a cost-effective solution for manufacturers striving for efficiency.

Another significant advantage lies in the scalability of injection molding processes. As demand for products fluctuates, manufacturers can adapt their production volumes with ease. The ability to quickly switch between different designs and materials without extensive machinery reconfiguration ensures that companies remain agile and competitive. Additionally, the integration of smart technologies and automation within injection molding systems in 2025 further streamlines production, resulting in faster turnaround times and lower operational costs. This combination of efficiency and flexibility positions injection molding as a vital technique for manufacturers aiming to thrive in a fast-paced market.

Top Mold Injection Techniques for Efficient Manufacturing in 2025

This chart illustrates the efficiency of various mold injection techniques projected for 2025. The data highlights the key benefits such as speed, cost-effectiveness, and material versatility associated with each technique.

Comparative Analysis of Injection Techniques: Cost-Effectiveness and Speed

In the rapidly evolving landscape of manufacturing, choosing the most suitable mold injection technique is crucial for maximizing both cost-effectiveness and operational speed. As we approach 2025, several techniques stand out in comparative analyses, particularly focusing on their economic viability and production efficiency. The traditional injection molding process remains widely used due to its low per-unit cost when scaling production. However, newer methods such as gas-assisted injection and multi-material injection are gaining traction for their ability to reduce material waste and enhance design flexibility, ultimately leading to significant savings.

Cost-effectiveness is not solely determined by material expenses but also by the speed of production cycles. Techniques such as rapid injection molding and 3D printing are becoming essential for manufacturers looking to shorten lead times. By integrating advancements in machine technology and material science, manufacturers can achieve shorter cycle times without sacrificing quality. Furthermore, production strategies that involve automation and smart manufacturing systems are proving to be increasingly valuable, allowing for a faster turnaround while maintaining a low-cost structure. The adoption of these innovative techniques is poised to define manufacturing success in an increasingly competitive market by 2025.

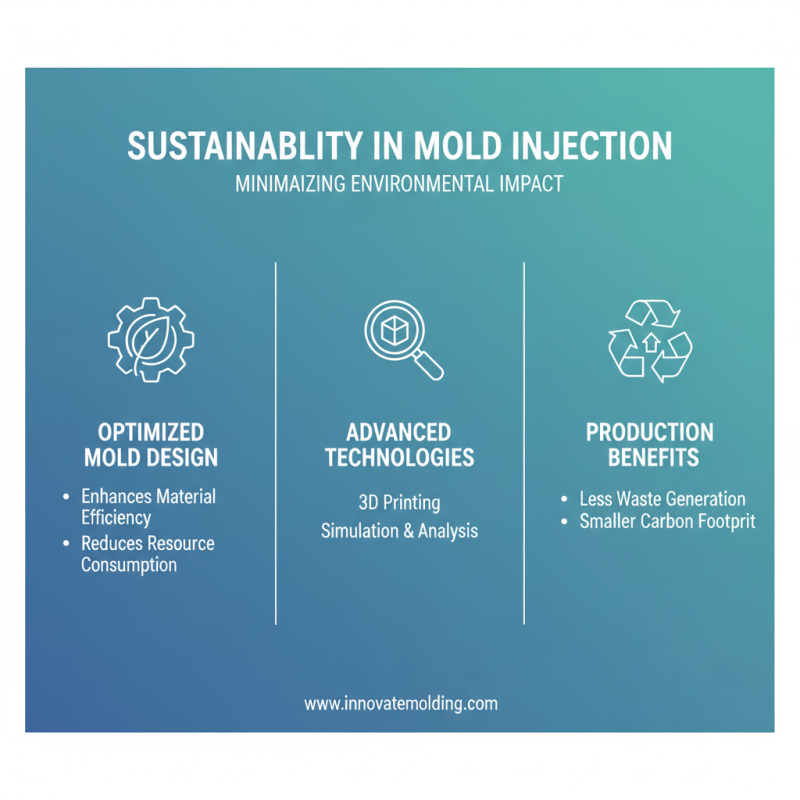

Sustainability in Mold Injection: Reducing Waste and Energy Consumption

Sustainability in mold injection is increasingly essential as manufacturers strive to minimize their environmental impact. By adopting innovative techniques, companies can significantly reduce waste generated during the injection molding process. One approach involves optimizing mold design, which can enhance the efficiency of material use. Advanced simulations and 3D printing technologies allow for the creation of more precise molds that require less material while ensuring quality in the final product. This not only conserves resources but also reduces the overall production footprint.

In addition to waste reduction, energy consumption is another critical factor in achieving sustainability in mold injection. The introduction of energy-efficient machinery and automated systems can greatly lower energy usage during production. Techniques such as utilizing hybrid and electric injection molding machines can make a significant difference, as they often operate with lower energy inputs compared to traditional machines. Furthermore, implementing real-time monitoring systems enables manufacturers to track energy usage and optimize processes, leading to further reductions in carbon emissions. By focusing on these sustainable practices, the mold injection industry can move towards a more environmentally friendly future while maintaining productivity and efficiency.

Future Trends: Automation and AI Integration in Mold Injection Processes

As the manufacturing landscape evolves, the integration of automation and artificial intelligence (AI) in mold injection processes is set to redefine efficiency in 2025. Automation technologies streamline repetitive tasks, reducing human error and increasing production speed. The application of AI allows for real-time data analysis, predicting maintenance needs and optimizing the injection process based on material behavior. This shift not only enhances productivity but also minimizes waste, contributing to more sustainable manufacturing practices.

Tips: To maximize the benefits of automation, manufacturers should invest in sensor technology that allows for data collection and analysis during the injection process. Additionally, training employees to work alongside AI systems can ensure a smoother transition and more effective utilization of new technologies.

The future of mold injection also points towards the use of smart robots that can adapt to varying production demands. These robots have the capability to adjust their operations on-the-fly, based on insights derived from AI algorithms. By implementing such systems, companies can achieve greater flexibility in their manufacturing lines, meeting customer demands without compromising quality.

Tips: Start small by introducing automated systems in specific areas of your operation to test their efficacy. Gathering feedback from your workforce during this phase can also highlight opportunities for further integration of AI-driven improvements.

Related Posts

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners

-

How Injection Mold Manufacturing is Revolutionizing Product Development in 2023

-

Top 10 Benefits of Mold Injection for Effective Product Manufacturing

-

2025 Top Trends in Mold Injection Manufacturing and Market Growth Insights

-

Top 5 Tips for Optimizing Injection Molding Tooling Efficiency

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products