Top 10 Benefits of Mold Injection for Effective Product Manufacturing

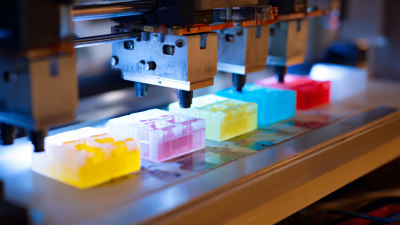

In the competitive landscape of product manufacturing, companies are constantly seeking innovative techniques that enhance efficiency and quality. One such method that has gained significant traction is mold injection. This advanced manufacturing process offers numerous advantages, making it a preferred choice for many industries, from automotive to consumer goods. With its ability to produce complex shapes with high precision, mold injection stands out as a game-changer that can streamline production timelines while ensuring product integrity.

The benefits of mold injection are manifold, particularly for businesses aiming to scale their operations without compromising on quality. By leveraging this technique, manufacturers can achieve consistency in their products, reduce waste, and optimize material usage. Additionally, the adaptability of mold injection allows for quick adjustments to designs and production runs, catering to evolving market demands. As we delve into the top 10 benefits of mold injection, it becomes evident that this method not only enhances operational efficiency but also contributes to the overall success of a product in today's dynamic marketplace.

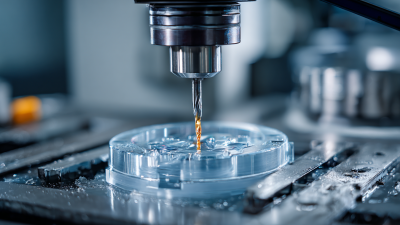

Advantages of Precision and Consistency in Mold Injection Processes

The precision and consistency offered by mold injection processes are pivotal in modern product manufacturing, particularly in industries such as medical devices and consumer goods. The ability to create intricate designs with high repeatability enables manufacturers to meet stringent regulatory standards while minimizing defects. For example, medical injection molding processes involve melting plastic resin pellets and injecting the molten material into molds to produce high-quality components. This method not only enhances the accuracy of the final products but also improves production efficiency, crucial in a rapidly evolving market.

Tips: Emphasize the importance of investing in specialized training for mold injection operatives to ensure operational excellence. Skilled technicians can significantly reduce waste and enhance the quality of produced items, leading to cost savings and improved customer satisfaction.

Additionally, as the injection molding industry embraces advancements such as smart manufacturing and sustainable practices, manufacturers are realizing the potential of low-pressure injection molding. This innovative approach reduces energy consumption and material waste, further contributing to the industry's growth trajectory. According to recent reports, the global injection molding market is projected to reach an impressive value, reflecting the increasing demand for customized and efficient manufacturing solutions.

Top 10 Benefits of Mold Injection for Effective Product Manufacturing

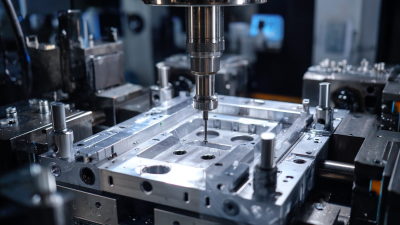

Enhancing Production Efficiency Through Advanced Mold Injection Techniques

Mold injection technology has revolutionized product manufacturing by significantly enhancing production efficiency. By utilizing advanced techniques, manufacturers can create complex components with consistent precision and rapid turnaround times. These benefits not only lead to cost savings but also allow for a greater focus on innovation and product quality. The ability to produce large quantities of items in a shorter timeframe has made mold injection a preferred choice across various industries, from automotive to consumer goods.

Tips: To maximize the benefits of mold injection, manufacturers should invest in state-of-the-art equipment and regularly train their staff on the latest techniques. This helps in maintaining the efficiency of the production process while ensuring that the products meet the desired quality standards. Additionally, conducting regular maintenance on the injection molds can prevent downtime and extend their lifecycle, further contributing to production efficiency.

Incorporating computer-aided design (CAD) and simulation tools can also streamline the mold design process. By using these advanced technologies, manufacturers can identify potential issues early on, thereby reducing the likelihood of costly errors during production. This proactive approach not only saves time but also enhances the overall effectiveness of the manufacturing operation.

Cost-Effectiveness of Mold Injection for Large-Scale Manufacturing

Mold injection stands out as a highly cost-effective method for large-scale manufacturing, significantly reducing production expenses while enhancing efficiency. The process involves creating molds that can be used to produce thousands of parts rapidly, making it ideal for businesses looking to maximize output. Once the initial mold is developed, the cost per unit decreases dramatically as production numbers increase, allowing manufacturers to benefit from economies of scale.

In addition to reduced costs, mold injection offers consistency and precision in manufacturing. The automated nature of the injection process ensures that each part produced meets strict quality standards, minimizing waste and rework. This efficiency not only saves money but also accelerates time-to-market, giving companies a competitive edge. Overall, leveraging mold injection can result in substantial savings and improved operational efficiency, making it a strategic choice for manufacturers aiming for large-scale production.

Versatility in Material Selection for Diverse Product Applications

Mold injection is an innovative manufacturing process that offers unmatched versatility in material selection, making it an ideal choice for a variety of product applications. This technique allows manufacturers to utilize a wide range of materials, from plastics to high-performance polymers, enabling the production of components that meet specific performance criteria. Whether creating intricate designs or large, structural parts, mold injection facilitates flexibility in material choice, ensuring that products not only adhere to design specifications but also are tailored for durability and functionality.

Furthermore, the adaptability of mold injection extends beyond just material selection. It empowers manufacturers to experiment with different blends and composites, enhancing properties such as strength, heat resistance, and weight reduction. This capability is particularly advantageous in sectors like automotive, consumer electronics, and medical devices, where material performance can significantly impact product success. As industries continue to evolve, the diverse applications supported by mold injection technology will play a crucial role in meeting the growing demand for innovative and efficient products.

Streamlining Design Flexibility and Customization with Mold Injection

Mold injection has increasingly become a crucial approach for enhancing design flexibility and customization in product manufacturing. By providing intricate designs and the ability to produce complex shapes, manufacturers can significantly shorten the time from concept to market. The global mold injection market is projected to grow, driven by the demand for specialized solutions in various sectors, including consumer goods and automotive industries. This flexibility supports innovation, allowing companies to respond quickly to shifting consumer preferences while maintaining high production efficiency.

In addition, integrating advanced technologies such as additive manufacturing with mold injection can lead to substantial improvements in design capabilities. According to recent industry reports, the North American metal powder market is anticipated to witness significant growth, suggesting a rising trend toward utilizing specialized materials in combination with traditional molding techniques. This evolution not only enhances the durability and functionality of products but also opens pathways for creating lightweight structures that save material and reduce costs.

Tips: When considering mold injection for your products, it's essential to evaluate the material compatibility and the desired finish. Collaborating with experienced suppliers can help ensure that your designs meet required specifications while leveraging the latest advancements in recycling and auxiliary equipment to maximize sustainability in your manufacturing processes.

Related Posts

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency

-

Exploring Innovations in Plastic Manufacturing: Sustainable Solutions for Tomorrow

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners

-

How Injection Mold Manufacturing is Revolutionizing Product Development in 2023

-

Exploring Innovative Molding Solutions: Transforming Ideas into Reality Through Advanced Techniques

-

Top 5 Benefits of Using Prototype Plastic Molding for Your Product Development