Top 10 Benefits of Prototype Injection Molding for Your Projects

In the rapidly evolving world of product development, the significance of prototype injection molding cannot be overstated. As experts increasingly recognize its advantages, professionals in diverse industries are turning to this method to enhance their project workflows. John Smith, a leading authority in the field of manufacturing technology, aptly points out, "Prototype injection molding not only accelerates the product development cycle but also significantly reduces costs associated with traditional methods." This innovative process enables designers and engineers to create functional prototypes that closely mimic the final product, allowing for comprehensive testing and refinement before mass production.

The benefits of prototype injection molding extend beyond mere cost savings and time efficiency. It facilitates a collaborative approach to product design by enabling stakeholders to visualize and interact with physical prototypes early in the process. This hands-on experience fosters better communication and alignment among team members, ensuring that the end product meets market demands and customer expectations. As we delve deeper into the top ten benefits of prototype injection molding, it becomes clear why this technique is becoming an essential strategy for businesses aiming to stay competitive in today's fast-paced marketplace.

Understanding Prototype Injection Molding and Its Processes

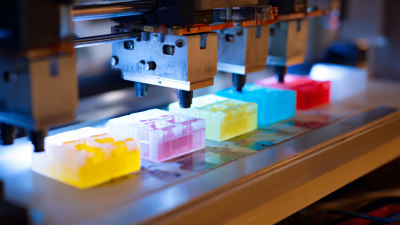

Prototype injection molding is a vital process in product development, allowing engineers and designers to create functional prototypes quickly and cost-effectively. This method relies on injecting molten plastic into a mold to create precise parts, which can then be analyzed for form and fit. According to a report from the Society of Plastics Engineers, about 75% of companies that utilize prototype injection molding report faster time-to-market for their products, which can significantly enhance a company’s competitive edge.

The process itself involves several critical steps, including design, mold fabrication, and the injection molding phase. Initially, 3D models of prototypes are created using CAD software, which allows for rapid alterations and optimizations. Once the design is finalized, molds are produced, usually through CNC machining or 3D printing, thereby reducing lead times and costs. A study from the American Society for Testing and Materials indicates that prototypes created through injection molding exhibit a level of accuracy and quality comparable to production parts, with tolerances often within ±0.1mm. This precision is crucial for testing the functionality and aesthetics of the product before full-scale production begins, ultimately resulting in more robust and market-ready designs.

Advantages of Rapid Prototyping Through Injection Molding

Rapid prototyping through injection molding offers numerous advantages that significantly enhance the development process of various projects. One of the primary benefits is the ability to produce high-quality prototypes in a fraction of the time compared to traditional methods. This speed allows designers and engineers to iterate their designs quickly, addressing any potential issues before moving to full-scale production. By facilitating faster feedback from stakeholders, rapid prototyping ensures that the end product closely aligns with market needs and expectations.

Moreover, injection molding provides exceptional precision and consistency in prototype production. This accuracy is crucial for testing the fit, form, and function of a design under real-world conditions. With the capability to create complex geometries and intricate details, injection molding allows teams to visualize and refine their concepts more effectively. The materials used in this process also mimic those intended for final production, enabling realistic assessments of performance and durability right from the prototype stage, ultimately supporting informed decision-making for subsequent development phases.

Cost-Effectiveness of Prototype Injection Molding for Various Projects

Prototype injection molding offers significant cost-effectiveness for a wide range of projects, making it an attractive option for manufacturers and designers alike. By utilizing this technique, companies can produce high-quality prototypes without incurring the high costs typically associated with traditional manufacturing methods. The process allows for rapid production of parts, significantly reducing lead times and enabling faster design iterations. This means that teams can evaluate their designs quickly, make necessary adjustments, and move to production without excessive expenditure.

Moreover, the scalability of prototype injection molding provides further financial advantages. As projects evolve, businesses can easily transition from small-scale prototypes to larger production runs, maintaining consistent quality while mitigating risks associated with large upfront investments. This flexibility allows companies to allocate resources efficiently, focusing on innovation and market responsiveness rather than being burdened by large inventory costs or lengthy production schedules. Ultimately, prototype injection molding serves not only as a cost-effective solution but also as a strategic tool for enhancing project outcomes through accelerated development processes.

Top 10 Benefits of Prototype Injection Molding

Material Versatility in Prototype Injection Molding Applications

Prototype injection molding offers a remarkable degree of material versatility, making it an ideal choice for a variety of projects. This process allows designers and engineers to work with a wide range of thermoplastics, elastomers, and even composite materials. Such flexibility enables the creation of prototypes that closely mimic the intended final product's characteristics, from mechanical strength to thermal stability. This ensures that any design flaws can be identified and rectified early in the development phase, ultimately saving both time and costs.

When considering materials for prototype injection molding, it's essential to select those that suit your project's requirements. For instance, if your prototype must endure high temperatures, opt for materials like polycarbonate or nylon. On the other hand, if flexibility is vital, materials such as thermoplastic elastomers should be considered.

**Tip:** Always conduct thorough research on material properties to ensure they align with your prototype's intended use. Additionally, consider running small-scale tests with different materials to observe their performance before committing to a final selection. This approach not only enhances the prototype's efficacy but also provides valuable insights that can inform future projects.

Top 10 Benefits of Prototype Injection Molding for Your Projects

| Benefit | Description | Material Versatility |

|---|---|---|

| Cost Efficiency | Lower production costs due to reduced material waste. | Compatible with a wide range of materials including plastics and metals. |

| Speed | Faster turnaround times for prototype development. | Supports multiple materials for varied prototypes quickly. |

| Precision | High accuracy in the production of complex shapes. | Materials can maintain tight tolerances throughout the production process. |

| Design Flexibility | Allows for modifications to design with ease. | Works with various polymers, accommodating different design needs. |

| Durability | Prototypes are robust and can withstand testing scenarios. | Material options include high-strength polymers. |

| Low Minimum Order Quantity | Produce small quantities without significant costs. | Suitable for small batches using diverse materials. |

| Environmental Impact | Less waste generated compared to traditional methods. | Recyclable materials can be used in production. |

| Functional Testing | Prototypes can be tested for specific functionality early. | Materials can mimic final product scenarios. |

| Aesthetic Appeal | Prototypes can be made to look like the final product. | Wide choice of finishes available with different materials. |

| Market Readiness | Get feedback before full-scale production. | Test various material options based on market needs. |

Improving Design Accuracy with Prototype Injection Molding Techniques

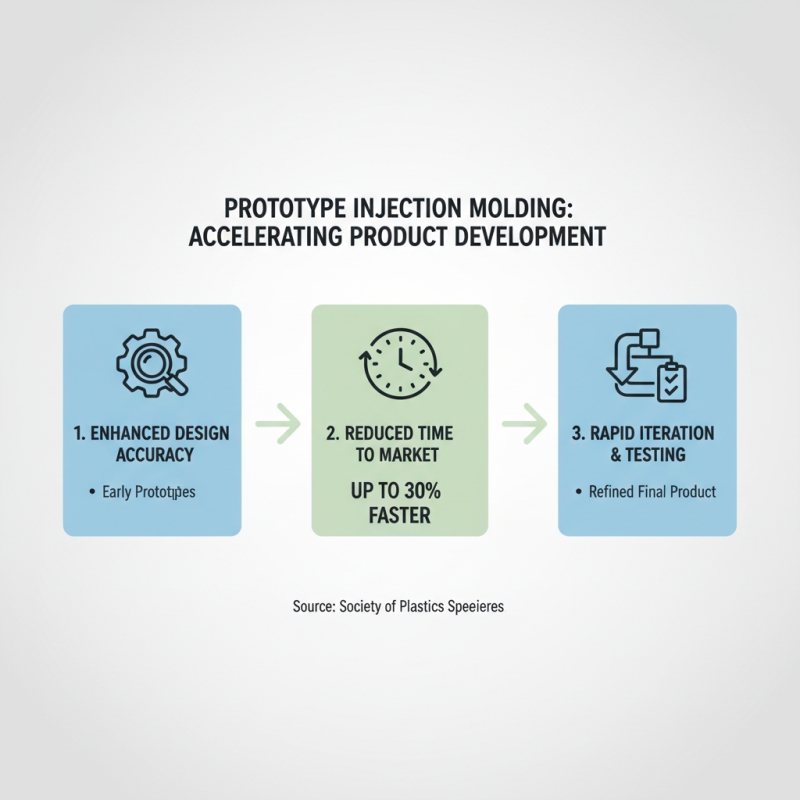

Prototype injection molding is an invaluable tool in the design and development phase of product manufacturing. By allowing engineers and designers to create early prototypes, this technique significantly enhances design accuracy. According to a report from the Society of Plastics Engineers, utilizing prototype injection molding can reduce time to market by up to 30%. This efficiency stems from the ability to rapidly iterate on designs and implement changes based on real-world testing, which in turn enhances the precision of the final product.

Moreover, a recent study published in the Journal of Manufacturing Science and Engineering highlights that prototype injection molding can improve dimensional accuracy by as much as 20% compared to traditional prototyping methods. This increase in accuracy is crucial, particularly in industries where tight tolerances are essential, such as automotive and aerospace. By providing a tangible representation of the design, teams can better visualize and test complex features, ultimately reducing errors that could arise later in the production process. Through these benefits, prototype injection molding solidifies its role as a critical factor in achieving design excellence and overall project success.

Related Posts

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products

-

Transforming Manufacturing Efficiency with Advanced Plastic Injection Machine Technology

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners

-

Top 5 Benefits of Using Prototype Plastic Molding for Your Product Development

-

Top 10 Benefits of Mold Injection for Effective Product Manufacturing

-

2025 Top 5 Innovative Prototype Molds Transforming Product Development