What is Plastic Mold Injection Machine? A Comprehensive Guide to Its Types and Applications

In the rapidly evolving world of manufacturing, the plastic mold injection machine has emerged as a pivotal technology that revolutionizes the production of plastic parts across various industries. This comprehensive guide aims to provide a clear understanding of what a plastic mold injection machine is, its different types, and its wide-ranging applications. As businesses seek more efficient and cost-effective production methods, mastering the intricacies of these machines becomes essential.

With an emphasis on innovation and sustainability, the upcoming years are expected to witness significant advancements in plastic mold injection technology. From automotive components to consumer goods, the versatility of plastic mold injection machines allows manufacturers to create complex shapes with high precision and repeatability. By exploring the features, benefits, and selection criteria of these machines, this guide will assist industry professionals in making informed decisions to enhance their production capabilities.

As we delve into the specifics of the top 10 plastic mold injection machines anticipated in 2025, it will become clear how these technologies are not only shaping the future of manufacturing but also meeting the evolving demands of the marketplace. Whether you are an existing player in the field or contemplating entry into the plastic production sector, understanding the dynamics of plastic mold injection machines is key to staying competitive and responsive to industry trends.

Understanding the Basics of Plastic Mold Injection Machines

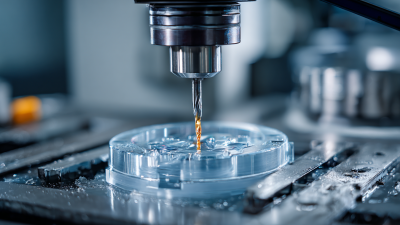

Plastic mold injection machines play a crucial role in the manufacturing of a wide range of products, particularly in industries like medical devices, automotive, and consumer goods. These machines operate by injecting molten plastic into a mold cavity, which then solidifies into the desired shape. The latest advancements in injection molding technology, such as turbocharged machining centers and energy-efficient servo-hydraulic models, have significantly enhanced the efficiency of the injection molding process. For instance, recent reports indicate that the adoption of high-speed cycle settings can reduce the overall production time, thereby increasing throughput without compromising on quality.

Moreover, educational initiatives, such as workshops and training programs, are essential for equipping industry professionals with the necessary skills to operate and maintain these sophisticated machines. Institutions are actively engaged in hands-on training that covers the fundamentals of injection molding processes. Additionally, awareness of environmental impact is growing, prompting manufacturers to calculate their carbon footprint and make informed decisions about their production practices. This shift towards sustainability is mirrored in the industry's move to develop energy-saving machines that not only improve efficiency but also reduce greenhouse gas emissions.

Exploring Different Types of Plastic Mold Injection Machines

Plastic mold injection machines are essential equipment in the manufacturing sector, specifically designed for producing plastic components. These machines can be categorized into several types based on their operational mechanism and application areas. The two primary types include hydraulic injection molding machines and electric injection molding machines. According to a research report from MarketsandMarkets, the global market for injection molding machines is projected to reach USD 18.9 billion by 2025, with electric machines gaining popularity due to their energy efficiency and precision.

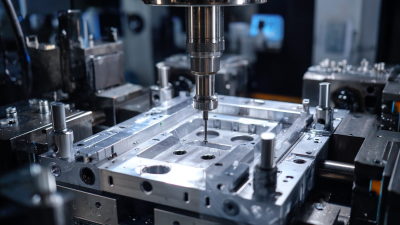

Hydraulic injection molding machines are often favored for their robust performance and ability to handle large volumes of production. They use hydraulic pressure to inject molten plastic into molds, making them suitable for producing larger items such as automotive parts. Conversely, electric injection molding machines offer enhanced accuracy and repeatability, which is critical for producing intricate designs. A study by Mordor Intelligence highlights that the electric segment is expected to grow at a CAGR of 4.9% from 2020 to 2025, driven by innovations in electronics and consumer goods manufacturing that require detailed plastic components.

Furthermore, there are specialized machines like multi-component injection molding machines that enable the production of complex parts composed of different materials. As industries evolve and the demand for customized products increases, the versatility of these machines proves crucial, making them a staple in sectors such as automotive, medical devices, and consumer products. The rising trend towards sustainability and the shift in manufacturing practices continue to shape the evolution of plastic mold injection machines, adapting to the specific needs of diverse applications.

Key Applications of Plastic Mold Injection in Various Industries

Plastic mold injection is a pivotal manufacturing process widely utilized across various industries due to its efficiency and versatility. This process enables the transformation of raw plastics into intricate shapes that cater to specific product requirements. Key applications of plastic mold injection span various sectors, including automotive, consumer goods, electronics, and medical devices. In the automotive industry, for instance, lightweight plastic parts produced through injection molding contribute to fuel efficiency and design flexibility.

The growing demand for plastic mold injection is further highlighted by recent market analyses. The plastic injection molding machine market is projected to see substantial growth through 2035, with advancements in machine types such as hydraulic, electric, and hybrid models catering to specific production needs. Industries are increasingly focusing on automation solutions, ranging from manual to fully automated systems, enhancing productivity while reducing labor costs. As manufacturers refine their processes, the ability to create complex, high-quality products at scale has solidified plastic mold injection's critical role in industrial applications.

Advantages and Disadvantages of Using Plastic Mold Injection Machines

Plastic mold injection machines play a vital role in manufacturing, particularly in the production of plastic parts. One of the main advantages of using these machines is their efficiency; they can produce large volumes of products with high precision in a short time frame. According to a report by MarketsandMarkets, the global injection molding machine market was valued at USD 19.65 billion in 2020 and is projected to reach USD 27.64 billion by 2025. This growth underscores the technology's productivity benefits for industries ranging from automotive to consumer goods.

However, there are also disadvantages worth considering. The initial setup cost of plastic mold injection machines can be substantial, often requiring significant capital investment in machinery and molds. A study by Grand View Research indicated that the high cost of machinery and tooling can deter small to medium enterprises from adopting this technology. Additionally, the process generates waste in terms of scrap material and energy consumption, which raises concerns regarding sustainability in today's eco-conscious market. These factors necessitate a careful evaluation of both the benefits and drawbacks when considering the deployment of plastic mold injection machines in manufacturing operations.

Plastic Mold Injection Machine Applications and Advantages

Future Trends and Innovations in Plastic Mold Injection Technology

The future of plastic mold injection technology is poised for remarkable advancements driven by innovation and sustainability. As industries demand more efficient and eco-friendly solutions, manufacturers are adopting automation and smart technologies, such as IoT and AI, to optimize production processes. This not only enhances precision in manufacturing but also reduces waste and energy consumption, enabling a greener approach to plastic production.

Tips: When exploring new technologies, always consider the long-term implications on efficiency and sustainability. Investing in machines with smart sensors can significantly improve real-time monitoring and predictive maintenance, leading to lower operational costs.

Moreover, bioplastics and biodegradable materials are gaining traction, allowing for environmentally conscious manufacturing. These materials can be processed with existing injection molding machines, making the transition smoother for businesses aiming to enhance their sustainability practices. As research into material science progresses, we can expect more innovative materials that maintain high performance while being less harmful to the environment.

Tips: Keep an eye on emerging trends in materials science, as they can impact your production choices. Collaborating with suppliers who focus on sustainable materials can help your brand stay ahead in the eco-conscious market.

Related Posts

-

Innovative Molding Tools for Streamlined Manufacturing Processes

-

Transforming Manufacturing Efficiency with Advanced Plastic Injection Machine Technology

-

Exploring Innovations in Plastic Manufacturing: Sustainable Solutions for Tomorrow

-

Exploring Innovative Molding Solutions: Transforming Ideas into Reality Through Advanced Techniques

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners