Top 5 Tips for Optimizing Injection Molding Tooling Efficiency

In the ever-evolving landscape of manufacturing, optimizing injection molding tooling efficiency is critical for maintaining competitive advantage. According to John Smith, a renowned expert in injection molding tooling, "Efficiency in tooling is not just about speed, but also about precision and consistency." As manufacturers strive to meet growing market demands, the optimization of tooling processes has emerged as a key area of focus.

Efficient injection molding tooling not only reduces production costs but also enhances product quality, ultimately leading to increased customer satisfaction. In a world where every second counts and every detail matters, understanding the nuances of injection molding tooling is essential for engineers and production managers alike. This article delves into the top five tips for maximizing efficiency in injection molding tooling, equipping professionals with the insights needed to navigate this complex yet rewarding field.

Understanding the Basics of Injection Molding Tooling Efficiency

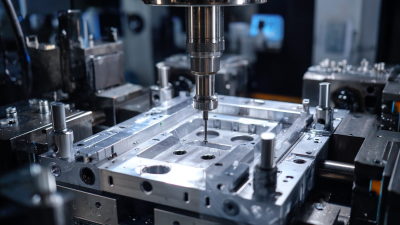

Injection molding tooling efficiency is essential for maximizing production rates and minimizing costs. The process begins with understanding the components of injection molding tools, which include the mold design, material selection, and maintenance practices. A well-designed mold can significantly reduce cycle times while enhancing the quality of the finished product. Factors such as wall thickness, draft angles, and the placement of gates must be optimized to ensure smooth material flow and uniform cooling, which are critical in accelerating production.

Moreover, regular maintenance of the tooling is vital in preventing downtime and maintaining efficiency. Scheduled inspections, cleaning, and repairs can help detect wear and tear that may compromise the tooling's performance. Additionally, using high-quality materials that resist wear and provide excellent thermal conductivity can further enhance the longevity and efficiency of the molds. By focusing on these fundamental aspects of injection molding tooling, manufacturers can achieve better performance and higher output, ultimately leading to increased profitability.

Key Factors Influencing Injection Molding Tooling Performance

Injection molding tooling performance is significantly influenced by several key factors that manufacturers must consider for optimal efficiency. One of the primary factors is the quality of the materials used in tooling construction. High-grade steels and alloys can enhance durability and resistance to wear, leading to longer tool life and reduced downtime for maintenance. Additionally, the choice of materials affects the thermal conductivity and temperature control within the mold, which are crucial for consistent polymer flow and achieving high-quality finished products.

Another critical aspect involves the design of the tooling itself. Streamlined and efficient designs that promote quick cycles and easy part ejection are essential for maximizing productivity. Incorporating features like conformal cooling channels can greatly improve heat distribution and reduce cycle times. Moreover, effective alignment of molds and proper clearance can prevent issues such as misalignment and flashing, ensuring that the tooling operates smoothly and produces parts that meet stringent specifications. By focusing on these key factors, manufacturers can enhance their injection molding processes and achieve superior efficiency.

Top 5 Tips for Optimizing Injection Molding Tooling Efficiency

Best Practices for Reducing Cycle Times in Injection Molding

To reduce cycle times in injection molding, one of the most effective practices is optimizing the mold design. A well-engineered mold can significantly shorten the cooling and injection stages. This can be achieved by utilizing advanced cooling systems that ensure uniform temperature distribution throughout the mold, allowing for quicker cooling and solidification of the polymer. Additionally, incorporating features like conformal cooling channels can further enhance thermal efficiency, reducing the time required for each cycle.

Another critical factor in minimizing cycle times is the careful selection of materials and processing parameters. Using high-performance resins that are compatible with rapid molding techniques can lead to faster cycle completion. Moreover, fine-tuning parameters such as injection speed, pressure, and temperature can drastically improve the efficiency of the injection process itself. Consistent monitoring and adjustment of these variables not only reduce cycle times but also enhance the overall quality of the molded parts, ensuring optimal output and reduced scrap rates.

Strategies for Enhancing Tool Life and Maintenance Schedules

To enhance tool life and maintenance schedules in injection molding, a proactive approach is essential. Regular maintenance checks can significantly extend the lifespan of the tooling equipment. Implementing a scheduled maintenance routine that includes inspection of mold components for wear, debris removal, and lubrication can help identify potential issues before they escalate. Monitoring tool performance metrics, such as cycle times and part quality, can also inform adjustments to maintenance schedules, ensuring tools are serviced based on their actual operating conditions rather than on a generic timeline.

Another effective strategy involves investing in training for maintenance staff to ensure they are well-equipped to handle the complexities of tooling systems. Knowledgeable technicians can perform maintenance more efficiently and recognize subtle signs of wear or malfunction that less experienced personnel might overlook. Additionally, establishing a feedback loop between the production and maintenance teams can facilitate sharing insights about tooling performance, leading to better-informed maintenance decisions. By fostering a culture of continuous improvement and vigilance in tool management, companies can significantly enhance the efficiency and lifespan of their injection molding tools.

Top 5 Tips for Optimizing Injection Molding Tooling Efficiency

| Tip No. | Tip Title | Description | Expected Outcome |

|---|---|---|---|

| 1 | Regular Maintenance | Conduct scheduled maintenance checks to identify wear and tear on tools. | Increased tool longevity and reduced downtime. |

| 2 | Optimize Cooling Systems | Ensure uniform cooling in the tooling to prevent warping and defects. | Improved product quality and shorter cycle times. |

| 3 | Use High-Quality Materials | Invest in high-quality steel or alloys for tooling to withstand production demands. | Reduced wear, better surface finish, and extended tool life. |

| 4 | Implement Proper Setup Procedures | Ensure that all setup procedures are followed to reduce errors during production. | Minimized production errors and scrap rates. |

| 5 | Train Operators Regularly | Provide ongoing training for operators to keep them up-to-date with best practices. | Enhanced efficiency and innovation in tool usage. |

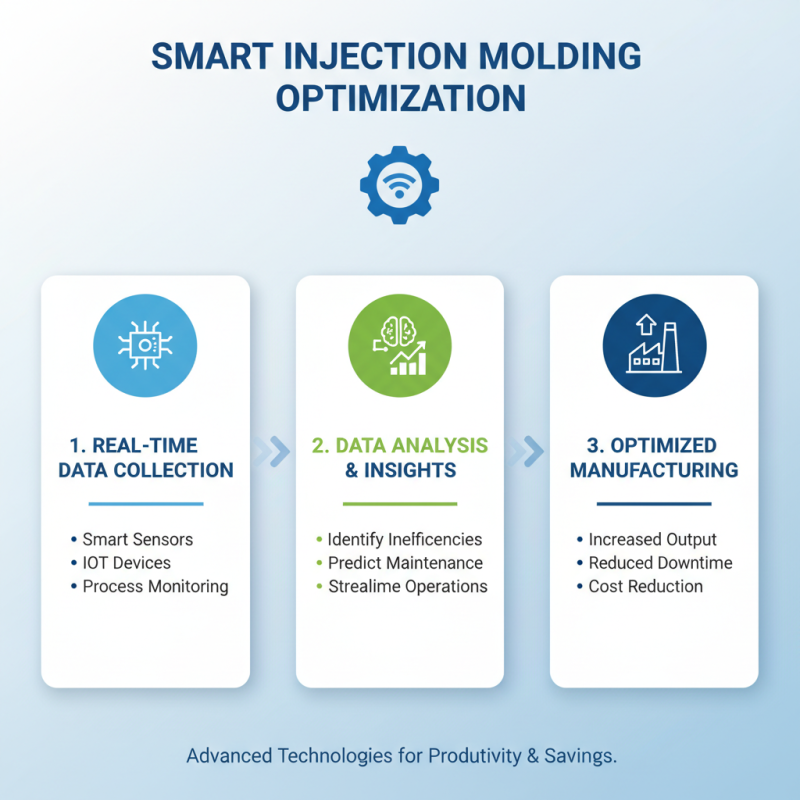

Utilizing Advanced Technologies to Optimize Injection Molding Processes

In the modern manufacturing landscape, optimizing injection molding processes is crucial for enhancing productivity and reducing costs. One of the most effective ways to achieve this is through the integration of advanced technologies. For instance, utilizing smart sensors and IoT devices allows manufacturers to collect real-time data on the molding process. This data can be analyzed to identify inefficiencies, predict maintenance needs, and streamline operations, ultimately leading to increased output and reduced downtime.

Moreover, the adoption of simulation software plays a vital role in optimizing tooling efficiency. By creating virtual models of the mold design and process parameters, manufacturers can conduct thorough analyses without incurring the costs or time associated with physical prototypes. This capability enables them to optimize cooling channels, adjust material flow, and identify potential defects before production begins. Additionally, incorporating automation technologies can minimize human error, standardize processes, and enhance repeatability, making the entire injection molding process more efficient and reliable, thus driving better overall manufacturing performance.

Related Posts

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners

-

Top 10 Benefits of Mold Injection for Effective Product Manufacturing

-

2025 Top Trends in Mold Injection Manufacturing and Market Growth Insights

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency

-

Exploring Innovative Molding Solutions: Transforming Ideas into Reality Through Advanced Techniques