2025 How to Optimize Mold Manufacturing Processes for Increased Efficiency

In the rapidly evolving landscape of mold manufacturing, optimizing production processes is essential for staying competitive and meeting increasing market demands. According to Dr. Michael Jensen, a leading expert in the field of mold manufacturing, "Efficiency isn't just a goal; it's a critical component of sustaining growth in an industry that demands precision and speed." As the industry faces pressures from advancements in technology and the push for sustainability, manufacturers must explore innovative strategies to streamline their operations.

The journey towards enhanced efficiency in mold manufacturing involves a multifaceted approach, including the adoption of cutting-edge technologies such as automation and smart manufacturing systems. By integrating these modern practices, organizations can reduce waste, improve turnaround times, and ultimately boost profitability. Furthermore, investing in employee training and fostering a culture of continuous improvement are pivotal in maximizing the output and quality of molded products.

As we delve into the intricacies of optimizing mold manufacturing processes, this exploration will shed light on practical methodologies, technological advancements, and best practices that are shaping the future of this crucial industry. Embracing these changes not only positions companies for success but also ensures a sustainable approach to meeting the ever-evolving needs of customers.

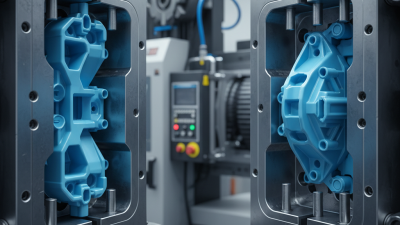

Overview of Mold Manufacturing Processes

Mold manufacturing processes are essential for the production of various components in industries such as automotive, consumer goods, and electronics. These processes typically encompass several stages, including design, material selection, machining, assembly, and testing. In 2023, the global injection molding market was valued at approximately $230 billion, and it is projected to grow at a CAGR of about 5% through 2025. This growth emphasizes the need for manufacturers to optimize their processes for improved efficiency and cost-effectiveness.

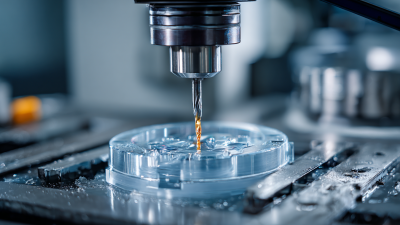

A key aspect of optimizing mold manufacturing is through the adoption of advanced technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM). These tools facilitate precise modeling and machining, reducing material waste and turnaround times. Moreover, integrating automation within the processes can significantly enhance productivity. According to a recent industry report, companies implementing automation in their manufacturing lines have seen efficiency increases of up to 30%.

Tip: Regular maintenance of molds is crucial to maintaining their performance and longevity. Ensure molds are inspected and cleaned periodically to avoid minor issues that can lead to costly production delays.

Another critical factor is the careful selection of materials. Utilizing high-quality raw materials can not only enhance the durability and functionality of the final products but also streamline the manufacturing process. Reports show that adopting optimized materials can lead to a 15-20% reduction in production costs while improving product quality.

Tip: Collaborate with your suppliers to ensure you have access to the latest and most efficient materials that align with your production needs.

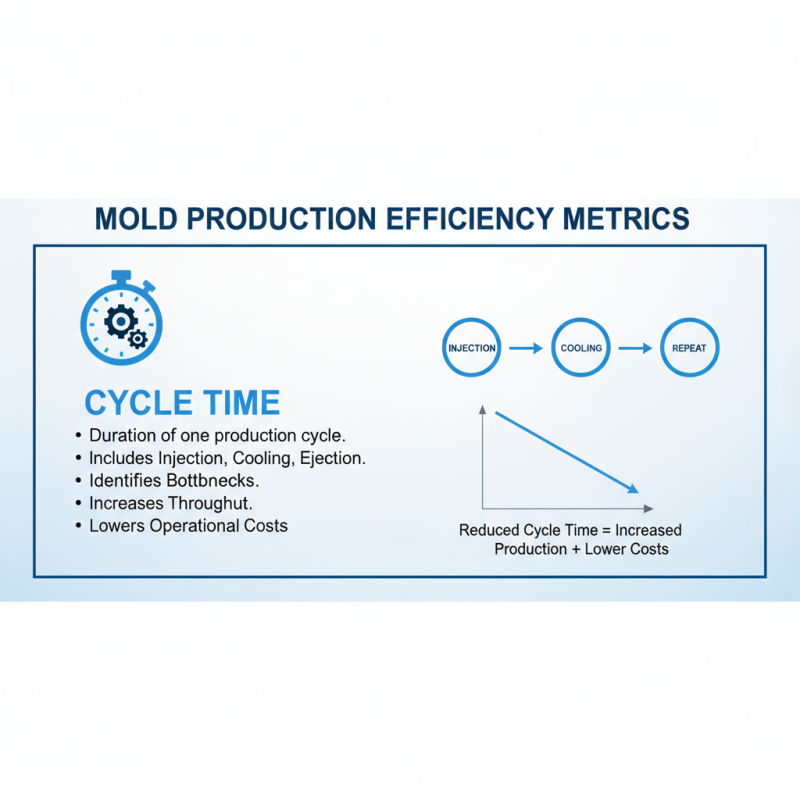

Identifying Key Efficiency Metrics in Mold Production

Identifying key efficiency metrics in mold production is crucial for optimizing manufacturing processes. One of the primary metrics is cycle time, which reflects the duration required to complete one production cycle, including injection, cooling, and ejection phases. By closely monitoring cycle times, manufacturers can identify bottlenecks in the production line, allowing for targeted adjustments that enhance throughput. Reducing cycle times not only increases production volume but also lowers operational costs, contributing to overall efficiency.

Another important metric is the scrap rate, which measures the percentage of defective pieces produced during the manufacturing process. High scrap rates indicate inefficiencies and can result from tool wear, material inconsistencies, or incorrect processing parameters. Implementing rigorous quality control measures and regular maintenance of equipment can help minimize scrap rates. Furthermore, adopting real-time monitoring systems can provide manufacturers with valuable data to detect anomalies early, facilitating prompt corrective actions that maintain product quality and reduce waste.

Lastly, machine utilization is a critical metric that assesses the percentage of time machines are actively producing compared to their available run time. High utilization rates indicate effective use of machinery, whereas low rates may suggest downtime due to maintenance or inefficiencies in workflow. By analyzing utilization data, manufacturers can optimize scheduling, streamline processes, and ensure that production resources are effectively deployed to maximize output and achieve higher efficiency levels in mold manufacturing.

Advanced Technologies for Streamlining Mold Manufacturing

The mold manufacturing industry is undergoing a transformation driven by advanced technologies, which aim to enhance efficiency and reduce production times. According to a report from the Society of Plastics Engineers, the adoption of automation in mold-making can increase productivity by up to 30%. Advanced modeling software and simulation tools allow manufacturers to optimize their designs before production, reducing errors and waste significantly. Furthermore, utilizing additive manufacturing for mold inserts can decrease lead times and costs, allowing for more complex geometries that traditional machining cannot achieve.

Tips: To further streamline the mold manufacturing process, consider implementing a digital twin for real-time monitoring and predictive maintenance. This technology can help detect potential failures before they occur, leading to reduced downtime and maintenance costs. Additionally, invest in training your workforce on the latest technologies to maximize operational efficiency.

The integration of Internet of Things (IoT) devices is another game-changer in mold manufacturing. By collecting data from various stages of the production process, IoT can provide insights that help in fine-tuning operations. A recent industry report highlighted that companies embracing IoT technologies could see a 20% reduction in operating costs. By leveraging these data-driven approaches, manufacturers can enhance decision-making and drive continuous improvement across their operations.

Implementing Lean Manufacturing Principles in Mold Design

Implementing lean manufacturing principles in mold design is crucial for optimizing mold manufacturing processes and enhancing efficiency. Lean manufacturing focuses on minimizing waste while maximizing productivity, which aligns perfectly with the goals of mold production. By streamlining processes and reducing unnecessary steps, manufacturers can significantly improve turnaround times and lower operational costs.

**Tip:** Start by conducting a thorough analysis of your current mold design processes. Identify areas where time and resources may be wasted, such as excessive handling, delays in communication, or redundant steps in the workflow. This analysis will help you pinpoint inefficiencies and develop targeted strategies to eliminate them.

Incorporating lean principles into mold design also means fostering a culture of continuous improvement among the design and manufacturing teams. Encouraging collaboration and open communication can lead to innovative solutions that not only enhance the mold design but also optimize the overall production process.

**Tip:** Implement regular feedback sessions where teams can discuss challenges and share best practices. This collaborative environment cultivates a mindset focused on improvement and empowers team members to contribute actively to lean initiatives. By prioritizing these principles, mold manufacturers can achieve greater efficiency and stay competitive in the ever-evolving market.

2025 How to Optimize Mold Manufacturing Processes for Increased Efficiency - Implementing Lean Manufacturing Principles in Mold Design

| Process Step | Current Efficiency (%) | Target Efficiency (%) | Improvement Techniques | Time Savings (Hours) |

|---|---|---|---|---|

| Design Phase | 75 | 90 | CAD Optimization, Early Prototyping | 30 |

| Material Selection | 80 | 95 | Supplier Collaboration, Material Testing | 20 |

| Machining | 70 | 85 | Automated Machinery, Tool Path Optimization | 50 |

| Assembly | 65 | 80 | Standard Work, 5S Methodology | 40 |

| Quality Control | 85 | 95 | Continuous Improvement, Statistical Process Control | 15 |

Best Practices for Quality Control in Mold Production

Quality control (QC) in mold production is crucial for ensuring that the final products meet the required specifications and standards. Implementing a robust QC process involves several best practices that can significantly enhance the overall efficiency of mold manufacturing. First, defining clear quality standards and specifications from the outset helps establish a baseline against which all mold outputs can be measured. This includes detailed parameters such as dimensions, surface finish, and material properties. Regular training of QC personnel also ensures that they are equipped with the latest knowledge and skills to effectively assess and monitor production processes.

Another essential practice in maintaining quality control is the integration of advanced technologies such as automated inspection systems and real-time monitoring tools. Utilizing such technologies not only reduces human error but also enables quicker identification of potential defects. Additionally, fostering a culture of continuous improvement within the production team encourages employees to participate actively in QC initiatives, leading to early detection of issues and a proactive approach to problem-solving. Engaging in regular audits and feedback sessions further reinforces this commitment to quality and allows for the refinement of processes over time, ultimately boosting the efficiency of mold manufacturing.

Related Posts

-

Exploring Innovative Molding Solutions: Transforming Ideas into Reality Through Advanced Techniques

-

How Injection Mold Manufacturing is Revolutionizing Product Development in 2023

-

How to Choose the Right Injection Molding Tooling for Your Project

-

The Ultimate Guide to Choosing the Best Union Tool for Your Project

-

Top 5 Benefits of Using Prototype Plastic Molding for Your Product Development

-

2025 Top 5 Innovative Prototype Molds Transforming Product Development