How to Optimize Injection Mold Design for Better Production Efficiency

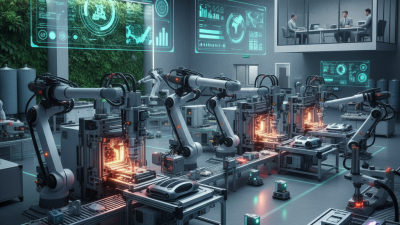

In the competitive landscape of manufacturing, achieving optimal production efficiency is paramount, and one of the critical factors influencing this efficiency is effective injection mold design. Injection mold design plays a significant role in determining the quality and cost-effectiveness of the final products, making it essential for manufacturers to thoroughly understand and implement best practices in this area. The design process not only impacts the manufacturability of the parts but also the speed of production, material usage, and the overall lifecycle of the mold itself.

A well-executed injection mold design minimizes production bottlenecks and maximizes output, thereby enhancing profitability. By focusing on aspects such as mold geometry, cooling systems, and material selection, manufacturers can improve cycle times and reduce waste significantly. Moreover, continuous advancements in technology and design methodologies offer innovative solutions that help manufacturers refine their injection mold design process further. This introduction highlights the importance of strategic design considerations in achieving greater production efficiency and lays the groundwork for exploring effective optimization techniques in injection molding.

Understanding the Basics of Injection Mold Design Principles

Injection molding is a critical process in manufacturing that requires a keen understanding of its design principles for optimal efficiency. The core design elements include mold geometry, material selection, and cooling systems. A well-designed mold not only enhances the quality of the final product but also reduces cycle time and material waste. Recent industry reports indicate that optimizing mold design can lead to a reduction in production costs by up to 30% while significantly improving turnaround times.

Tips for effective mold design include focusing on uniform wall thickness, which reduces stress in the molded parts and helps achieve better fill rates. Additionally, incorporating features like venting and appropriate cooling channels can minimize defects and ensure uniform temperature distribution during the injection process. According to a study by the Society of Plastics Engineers, efficient cooling can decrease cycle time by as much as 25%, clearly reflecting the importance of incorporating advanced cooling strategies in the design phase.

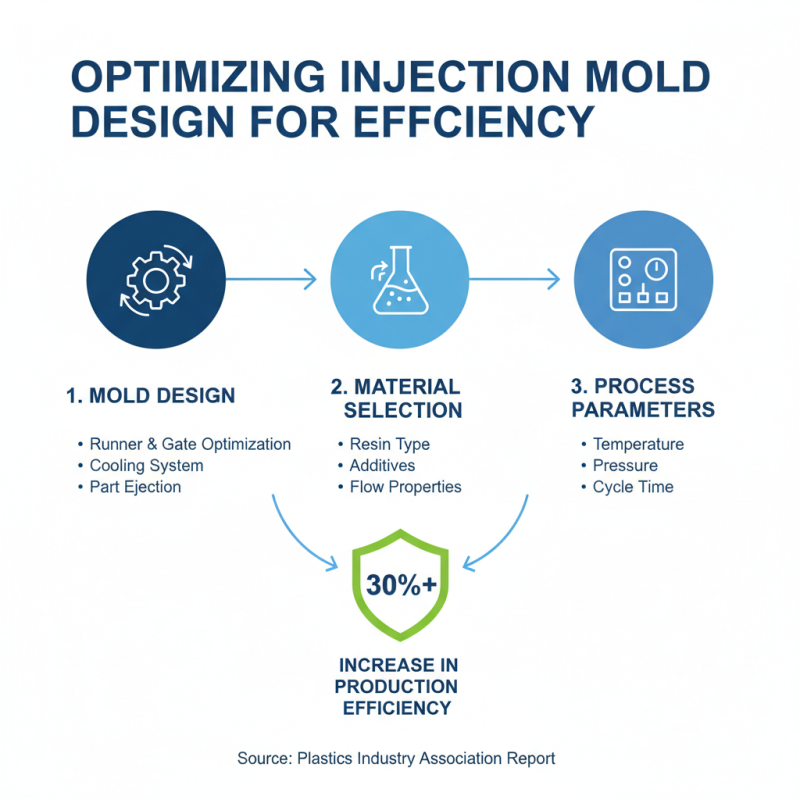

Moreover, selecting the right materials is crucial. Advanced materials can offer better flow characteristics, strength, and thermal stability, which directly affect the performance of the mold. The latest data from the Plastics Industry Association suggests that the choice of high-performance polymers can enhance the durability of molds, leading to increased production volume and efficiency. By mastering these fundamental principles, manufacturers can greatly enhance their production processes and achieve higher efficiency in injection molding.

Key Factors Affecting Production Efficiency in Injection Molding

Optimizing injection mold design is crucial for enhancing production efficiency, which can significantly impact a manufacturer's bottom line. Several key factors influence the efficiency of injection molding processes, including mold design, material selection, and process parameters. According to a report by the Plastics Industry Association, optimizing these aspects can improve production efficiency by up to 30%.

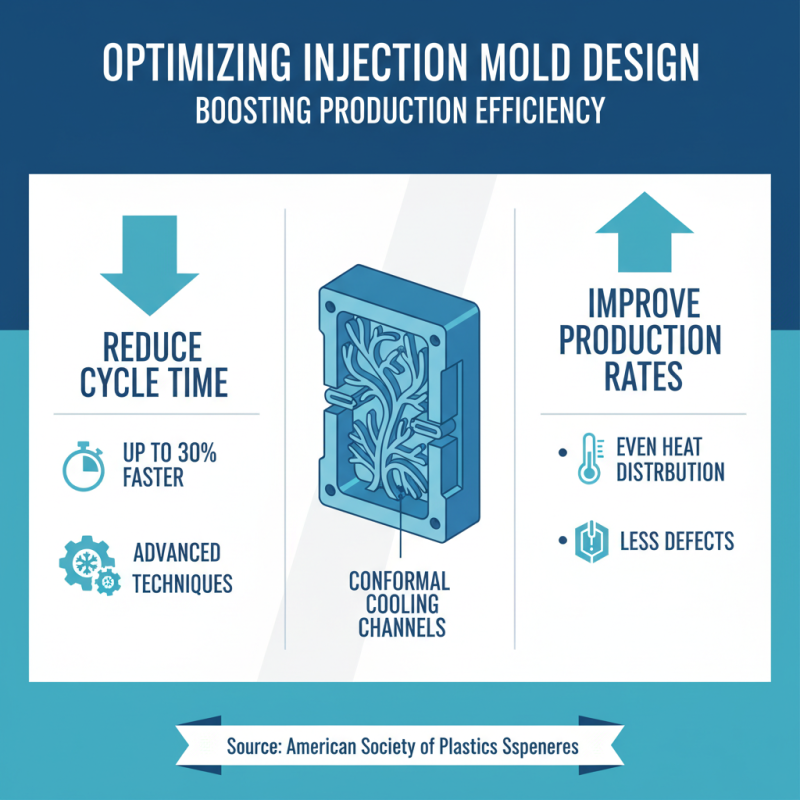

One of the primary elements in mold design is the cooling system. Effective cooling can reduce cycle times, which directly correlates with increased output. A well-designed cooling channel layout can minimize temperature fluctuations and ensure uniform cooling, thereby enhancing the quality of the final product. Implementing techniques such as conformal cooling, where the cooling channels are designed to follow the contours of the mold, can further improve efficiency.

Tips: Consider utilizing simulation software to model thermal flow in your mold design. This can help identify hot spots and optimize cooling channel placements before physical production begins.

Another critical factor is the selection of materials. Choosing the right polymer not only affects the final product's strength and durability but also influences the processing speed. Resins with faster injection rates can lead to shorter cycle times. A study from the American Society of Plastics Engineers emphasizes the importance of selecting materials that are suited for specific applications, potentially boosting production efficiency by 15% or more.

Tips: Regularly review material specifications and evaluate new formulations that might offer enhanced processing characteristics for your specific molding applications.

Best Materials and Technologies for Optimizing Mold Design

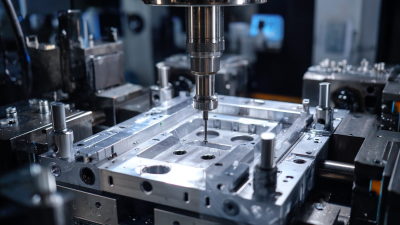

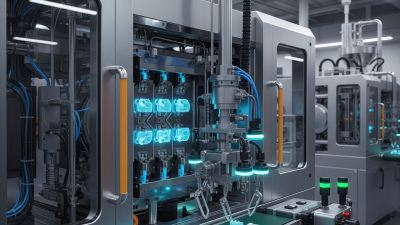

When it comes to optimizing injection mold design, selecting the right materials and technologies is crucial for enhancing production efficiency. One of the most common materials used in mold making is steel, prized for its durability and strength. High-carbon steel is often chosen for its ability to withstand high pressures and maintain precision over time. For applications requiring quick production cycles, aluminum molds can be a beneficial alternative due to their lighter weight and easier machining capabilities, allowing for faster turnaround times. Furthermore, advancements in composite materials are gaining traction, as they provide excellent thermal conductivity and can significantly reduce cooling times in the molding process.

In addition to material selection, integrating modern technologies into mold design can greatly enhance production efficiency. Computer-aided design (CAD) and computer-aided manufacturing (CAM) software allow engineers to simulate mold functionality before physical production, identifying potential design flaws early in the process. Additionally, utilizing 3D printing for prototyping and creating mold parts can expedite the development phase and lower costs. Employing hot runner systems can also optimize the injection process by reducing waste and improving cycle time. Ultimately, combining the right materials with advanced design technologies lays the foundation for an efficient and cost-effective injection molding process.

How to Optimize Injection Mold Design for Better Production Efficiency

| Material Type | Mold Technology | Production Efficiency (%) | Cycle Time (seconds) | Cost Effectiveness |

|---|---|---|---|---|

| Steel | Conventional Injection Molding | 85 | 30 | Moderate |

| Aluminum | Rapid Prototyping | 90 | 25 | High |

| Borosilicate Glass | Injection Blow Molding | 80 | 35 | Low |

| Polycarbonate | Multi-Cavity Molding | 88 | 28 | Moderate |

| Nylon | Gas-Assisted Injection Molding | 82 | 32 | Moderate |

Techniques to Reduce Cycle Time and Improve Production Rates

Optimizing injection mold design is essential for enhancing production efficiency, particularly when focusing on reducing cycle time and improving production rates. According to a study by the American Society of Plastics Engineers, cycle times can be reduced by up to 30% through the implementation of advanced cooling techniques. By incorporating conformal cooling channels within molds, heat distribution becomes more even, leading to faster cooling times. This not only speeds up the overall process but also reduces the risk of defects that can occur when cooling is uneven.

In addition to cooling improvements, the choice of materials for both the molds and the parts can significantly impact production rates. A report from the Society of Manufacturing Engineers highlights that using lighter materials for mold construction can enhance equipment speed and reduce wear, contributing to a more efficient cycle. Furthermore, utilizing high-performance polymers for the molded parts allows for quicker melt flow and better mold filling, significantly shortening the cycle time. Overall, through thoughtful design modifications and material selections, manufacturers can achieve higher production rates and reduce operational costs.

Implementing Effective Testing and Validation in Mold Design Process

In the realm of injection mold design, effective testing and validation play a crucial role in enhancing production efficiency. According to a report by the Society of Plastics Engineers, approximately 70% of production issues stem from design inadequacies that could have been identified during the testing phase. Implementing rigorous testing protocols allows manufacturers to address potential flaws early in the design process, thus reducing costly modifications later in the production cycle.

One effective strategy is the use of simulation software to predict mold performance under various conditions. A study conducted by the American Society for Quality indicates that companies utilizing advanced simulation tools have seen a 30% decrease in time-to-market, as they can accurately forecast mold behaviors and adjust designs preemptively. Additionally, iterative prototyping, such as 3D printing, further enhances testing capabilities, allowing for rapid adjustments based on real-world testing outcomes. This proactive approach not only mitigates risks but also ensures that molds meet stringent quality and efficiency standards before they enter full-scale production.

Related Posts

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency

-

How Injection Mold Manufacturing is Revolutionizing Product Development in 2023

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products

-

2025 Top Trends in Mold Injection Manufacturing and Market Growth Insights

-

Top 10 Plastic Mold Injection Machines to Watch in 2025

-

The Ultimate Guide to Choosing the Best Union Tool for Your Project