Innovative Molding Tools for Streamlined Manufacturing Processes

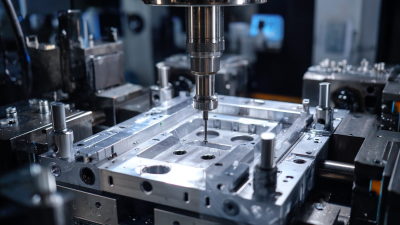

In today’s fast-evolving manufacturing landscape, the integration of innovative molding tools is pivotal for enhancing operational efficiency and maintaining competitive advantage. The convergence of digital technologies with traditional manufacturing processes has given rise to the "Digital + Best" approach, empowering organizations to streamline their workflows and reduce production cycles. Molding tools have evolved significantly, incorporating advanced materials and automation to facilitate precision and flexibility in design.

As manufacturers strive to meet the demands of customization and sustainability, the adoption of state-of-the-art molding tools is not merely an option but a necessity. This introduction delves into the transformative impact of these tools on manufacturing processes, illustrating how their implementation can lead to significant improvements in productivity and quality. Through examining recent advancements and case studies, we uncover the strategic importance of investing in innovative molding solutions to navigate the complexities of modern production challenges effectively.

Emerging Technologies in Molding Tool Design for Efficiency

Emerging technologies in molding tool design are revolutionizing the manufacturing landscape by enhancing efficiency and reducing production times. Advanced materials such as carbon fiber and high-performance polymers provide durability and lighter weights, leading to faster cycle times and lower energy consumption during the molding process.

Additionally, the integration of smart sensors and IoT (Internet of Things) solutions allows for real-time monitoring and optimization of molding conditions, enabling manufacturers to maintain quality while minimizing waste.

Furthermore, additive manufacturing techniques, including 3D printing, are becoming integral in the creation of intricate mold designs that were previously difficult or impossible to achieve. This allows for greater design flexibility and rapid prototyping, significantly shortening product development cycles. By combining these innovative approaches, manufacturers can not only improve their workflow but also adapt more quickly to market demands, ultimately leading to enhanced competitiveness in a rapidly changing industry.

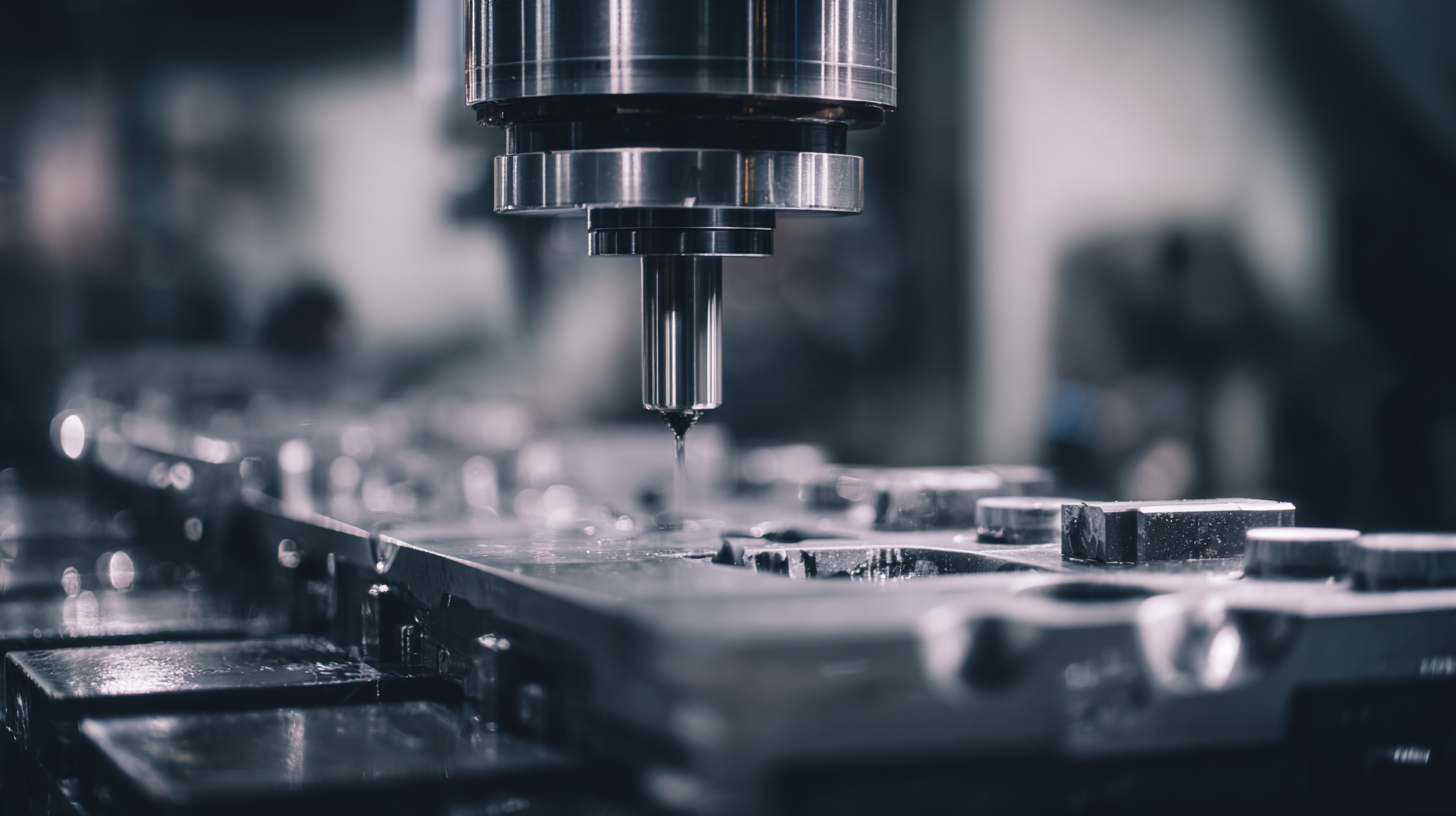

The Role of Automation in Modern Molding Processes

In today's fast-paced manufacturing landscape, automation plays a pivotal role in modern molding processes. By leveraging advanced technologies such as robotic automation and intelligent systems, manufacturers can significantly enhance productivity and precision. Automated molding processes reduce human error and streamline workflow, allowing for consistent quality and faster turnaround times. This transformation leads to cost savings and increased competitiveness in the market.

**Tips:** When integrating automation into your molding processes, start small. Implement automated solutions in specific areas, such as injection molding or quality inspection, to assess their impact on your overall operations. Regularly evaluate the results to identify further opportunities for enhancement.

Additionally, investing in smart sensors can provide real-time data on mold conditions, enabling proactive adjustments and minimizing downtime. Embracing these technologies empowers manufacturers to not only meet growing demand but also innovate their product offerings and adapt to market changes fluidly.

**Tips:** Consider training your workforce in new technologies to ensure a smooth transition to automated systems. Engagement and education will allow your team to effectively utilize automation tools and maximize their potential benefits in your manufacturing processes.

| Tool Type | Material Used | Automation Level | Cycle Time (seconds) | Production Capacity (units/hour) | Cost Efficiency (%) |

|---|---|---|---|---|---|

| Hydraulic Molding Press | Steel | High | 30 | 250 | 25 |

| Electric Injection Molding Machine | Aluminum | Very High | 20 | 300 | 40 |

| Rotational Molding Machine | Polyethylene | Medium | 45 | 150 | 15 |

| 3D Printing | PLA | High | 60 | 50 | 30 |

| Compression Molding Machine | Rubber | Medium | 35 | 200 | 20 |

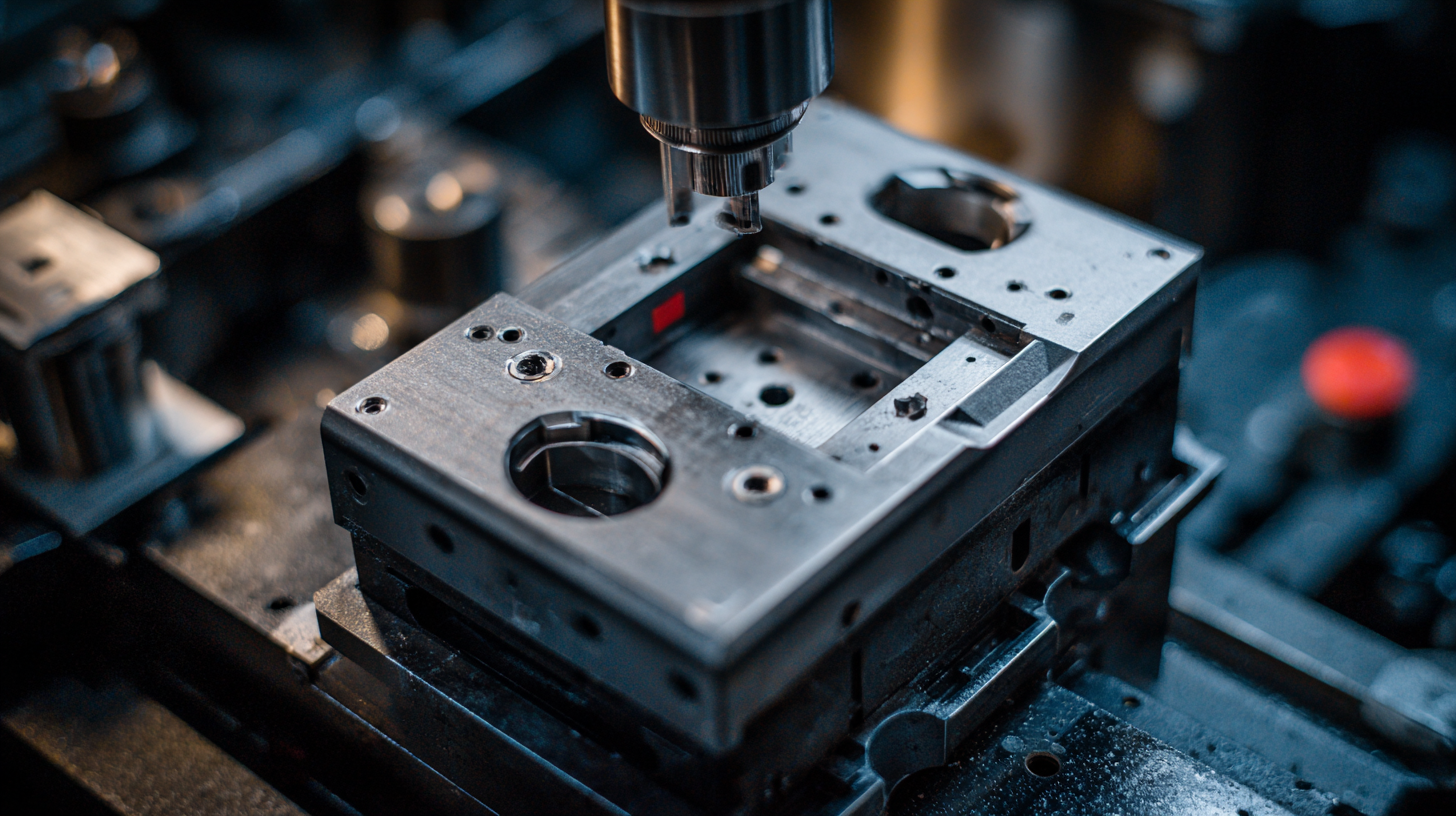

Benefits of Advanced Materials in Tool Manufacturing

The use of advanced materials in tool manufacturing significantly enhances the efficiency and performance of molding tools. Materials such as high-performance polymers, composites, and specialized alloys offer remarkable durability and resistance to wear, which is essential in high-volume production environments. These materials not only extend the lifespan of the tools but also reduce maintenance costs, enabling manufacturers to allocate resources more effectively.

The use of advanced materials in tool manufacturing significantly enhances the efficiency and performance of molding tools. Materials such as high-performance polymers, composites, and specialized alloys offer remarkable durability and resistance to wear, which is essential in high-volume production environments. These materials not only extend the lifespan of the tools but also reduce maintenance costs, enabling manufacturers to allocate resources more effectively.

Additionally, the incorporation of innovative materials contributes to lighter tool designs without compromising strength. This reduction in weight can lead to lower energy consumption during the manufacturing process, further streamlining operations. Moreover, the adaptability of advanced materials allows for the development of tools with complex geometries that improve the precision of molded components. This capability not only fosters creativity in product design but also meets the increasing demand for customization in various industries. As manufacturers continue to adopt these advanced materials, the overall efficacy of molding processes is set to improve, leading to higher-quality products and greater competitiveness in the market.

Integrating Smart Systems for Real-Time Monitoring in Production

The integration of smart systems into production processes has revolutionized manufacturing, enabling real-time monitoring and advanced control. The market for process control systems is experiencing significant growth, driven by the increasing demand for automation across various sectors, including oil and gas, chemicals, automotive, and food production. Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC) dominate this market, providing essential tools for manufacturers aiming to enhance operational efficiency and minimize production costs.

In recent initiatives, industries are increasingly collaborating with educational institutions to establish digital technology training bases. This synergy not only fosters innovation but also equips the workforce with essential digital competencies necessary for a smart manufacturing environment. Projects like smart farms are exemplifying the impact of digitization by demonstrating precision agriculture techniques that rely on automation to optimize yield and reduce labor costs. Such advancements illustrate how smart systems can lead to more streamlined operations and a transformative shift within traditional manufacturing landscapes.

Innovative Molding Tools Performance Analysis

Sustainability Practices in Innovative Molding Tool Development

The development of innovative molding tools is increasingly intertwined with sustainability practices, ensuring that manufacturing processes are not only efficient but also environmentally responsible. Modern molding tools are being designed with sustainable materials and practices that reduce waste production and energy consumption. By incorporating biodegradable or recyclable materials, manufacturers can minimize their ecological footprint while maintaining high-quality production standards. This shift not only addresses regulatory demands but also aligns with the growing consumer preference for environmentally friendly products.

Moreover, the design of these tools often includes advanced technologies, such as energy-efficient heating systems and precision engineering, which further enhance sustainability. For instance, incorporating automation and smart manufacturing systems can optimize production efficiency, reducing overall resource usage. Emphasizing closed-loop systems in the manufacturing process allows for continuous recycling of materials, thereby promoting a circular economy. As the industry evolves, the partnership between innovative molding tool development and sustainable practices will play a crucial role in transforming manufacturing into a more eco-conscious sector.