Exploring Innovative Molding Solutions: Transforming Ideas into Reality Through Advanced Techniques

In today’s rapidly evolving landscape, the demand for innovative molding solutions is at an all-time high as industries seek to transform their ideas into tangible products. The intersection of digital technology and advanced manufacturing techniques has opened new avenues for creativity and efficiency in the molding process. By leveraging cutting-edge technologies, businesses can optimize their production methods, reduce lead times, and enhance the quality of their final products.

This exploration into molding solutions dives deep into the methodologies that are shaping the future of product development. From 3D printing to advanced thermoplastics, the capacity for customization and precision in molding has never been greater. By integrating digital tools such as simulation software and data analytics, manufacturers are redefining what is possible, creating robust, sustainable, and cost-effective solutions that meet the ever-changing demands of consumers.

Ultimately, the journey of innovation in molding solutions not only empowers designers and engineers but also paves the way for a new era of manufacturing, where ideas flourish and the impossible becomes achievable. Embracing these advanced techniques is essential for any enterprise looking to stay ahead in a competitive market, making it imperative to understand and implement these transformative technologies.

Innovative Molding Techniques: Shaping the Future of Manufacturing

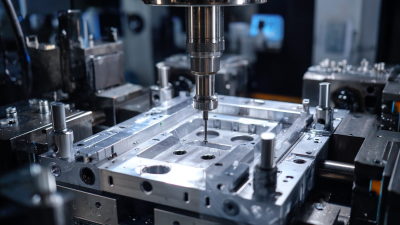

Innovative molding techniques are transforming the landscape of manufacturing by reshaping how products are conceived and produced. As industries pivot towards more sustainable and efficient methods, low-pressure injection molding has emerged as a leading solution, allowing manufacturers to create lightweight and durable products while minimizing waste. This advancement reflects a broader trend in the manufacturing sector, where companies are increasingly prioritizing environmental consciousness and efficiency in their processes.

The recent developments in ceramic additive manufacturing further exemplify these innovative techniques, with several companies at the forefront of this technology. By leveraging 3D printing methods, they are redefining the capabilities of technical ceramics, leading to more sophisticated applications in industries ranging from automotive to medical. This intersection of technology and manufacturing not only fosters creative design possibilities but also enhances the overall performance of products, thereby shaping a more advanced future for various sectors.

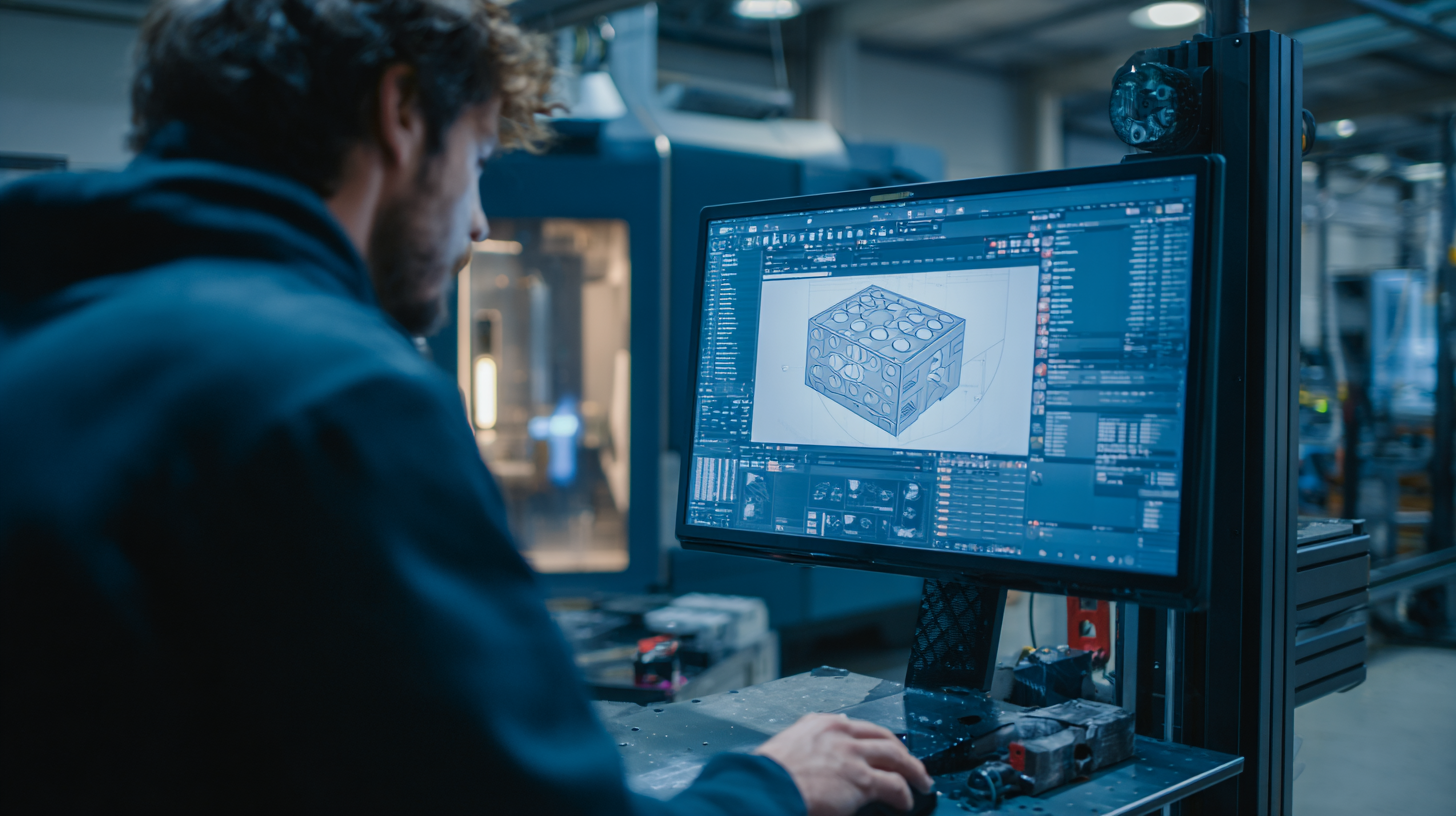

Harnessing Digital Technologies for Enhanced Molding Processes

The integration of digital technologies into molding processes is revolutionizing the manufacturing landscape. By utilizing advanced software and automation, manufacturers can enhance their design capabilities, streamline production cycles, and significantly improve product quality. Computer-Aided Design (CAD) systems allow for precise modeling of intricate geometries, ensuring that creative ideas are accurately translated into physical products. Furthermore, the implementation of simulation tools helps identify potential issues before the actual production begins, reducing waste and minimizing the need for costly corrections.

Moreover, the rise of additive manufacturing techniques, commonly known as 3D printing, opens up new possibilities for molding solutions. This innovative approach allows for rapid prototyping and the production of complex parts that traditional molding methods cannot achieve. With digital technologies enabling on-demand production, businesses can respond swiftly to market demands while maintaining cost-efficiency. As manufacturers continue to leverage these digital advancements, the future of molding processes looks promising, paving the way for more efficient and sustainable production methodologies.

Sustainable Practices in Molding: Reducing Waste through Innovation

Sustainable practices in molding are becoming increasingly crucial as industries face pressure to innovate while minimizing environmental impact. One of the most promising advancements is low-pressure injection molding, which not only enhances precision but also significantly reduces material waste. As the global plastic injection molding market is projected to grow from USD 10.50 billion in 2025 to around USD 13.70 billion by 2033, manufacturers are recognizing that eco-friendly innovations are essential to remain competitive in today's market.

In addition to efficient molding techniques, the integration of biodegradable materials stands out as a key strategy for waste reduction. Innovations such as biodegradable nails exemplify how aesthetics can meet sustainability, using materials designed to decrease plastic waste. Furthermore, industries are increasingly embracing circular economy principles by collaborating with recycling initiatives. For instance, some firms are transforming waste into valuable resources, reflecting a broader trend in material science towards responsible production. The future of molding not only hinges on advanced techniques but also on an unwavering commitment to sustainability.

Case Studies: Successful Transformations Using Advanced Molding Solutions

In the realm of innovative molding solutions, numerous case studies highlight successful transformations that hinge on advanced techniques.

For example, a startup specializing in eco-friendly products leveraged cutting-edge injection molding processes to create biodegradable packaging solutions. By utilizing sustainable materials and precise molding techniques, the company not only minimized waste but also appealed to environmentally conscious consumers, demonstrating that advanced molding can foster both innovation and sustainability.

Tips: When considering molding solutions, always evaluate the material compatibility with your design. This ensures that the final product not only meets aesthetic requirements but also functional durability. Additionally, engage with experts who can guide you through the latest technologies, as their insights can lead to significant improvements in efficiency and output.

Another remarkable case is an automotive manufacturer that implemented 3D printing combined with traditional molding. This hybrid approach allowed for rapid prototyping and reduced production time for car components. By advancing their molding capabilities, they achieved a more agile manufacturing process, enabling quicker responses to market demands and enhancing overall productivity.

Tips: Keep an open mind to hybrid solutions that blend different manufacturing techniques. This versatility can unlock new possibilities for product development and cost savings. Moreover, investing in employee training on new technologies can significantly enhance the efficacy of these advanced molding solutions.

The Future Landscape of Molding: Trends and Predictions in Technology

The future landscape of molding technology is rapidly evolving, driven by advancements in materials and processes that have the potential to revolutionize the industry. With the U.S. metal forging market valued at $7.75 billion in 2022 and projected to grow at a CAGR of 6.1%, innovation in molding solutions is at the forefront of production capabilities. Techniques such as precision injection molding and integrated die-casting are shaping new opportunities across various sectors, from automotive to consumer electronics.

As we look ahead to 2025 and beyond, the integration of technologies like 3D printing is expected to further transform molding applications. Industry leaders are recognizing the importance of adopting new methodologies that enhance efficiency and reduce production costs. Reports indicating a CAGR of 7.82% in the global mold steel market reinforce the notion that investment in advanced molding technologies will not only meet the demands of future production but also define the competitive landscape. With these evolving trends, it is clear that the molding sector is on the brink of significant advancements that will shape its trajectory in the coming years.

Exploring Innovative Molding Solutions: Transforming Ideas into Reality Through Advanced Techniques - The Future Landscape of Molding: Trends and Predictions in Technology

| Molding Technique | Advantages | Applications | Future Trends |

|---|---|---|---|

| 3D Printing | High customization, rapid prototyping | Automotive, Aerospace, Medical devices | Increased material versatility, bio-printing |

| Injection Molding | High efficiency, consistent quality | Consumer goods, Electronics, Packaging | Integration with IoT, Smart materials |

| Blow Molding | Suitable for hollow objects, cost-effective | Bottles, Containers, Automotive components | Sustainability practices, Biodegradable materials |

| Rotational Molding | Large parts, Durable products | Tanks, Playground equipment, Storage containers | Innovative designs, Reduced energy consumption |

Related Posts

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency

-

How Injection Mold Manufacturing is Revolutionizing Product Development in 2023

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners

-

Innovative Molding Tools for Streamlined Manufacturing Processes

-

Transforming Manufacturing Efficiency with Advanced Plastic Injection Machine Technology

-

Exploring the Future of Union Tool: Innovations and Applications in Today’s Industry