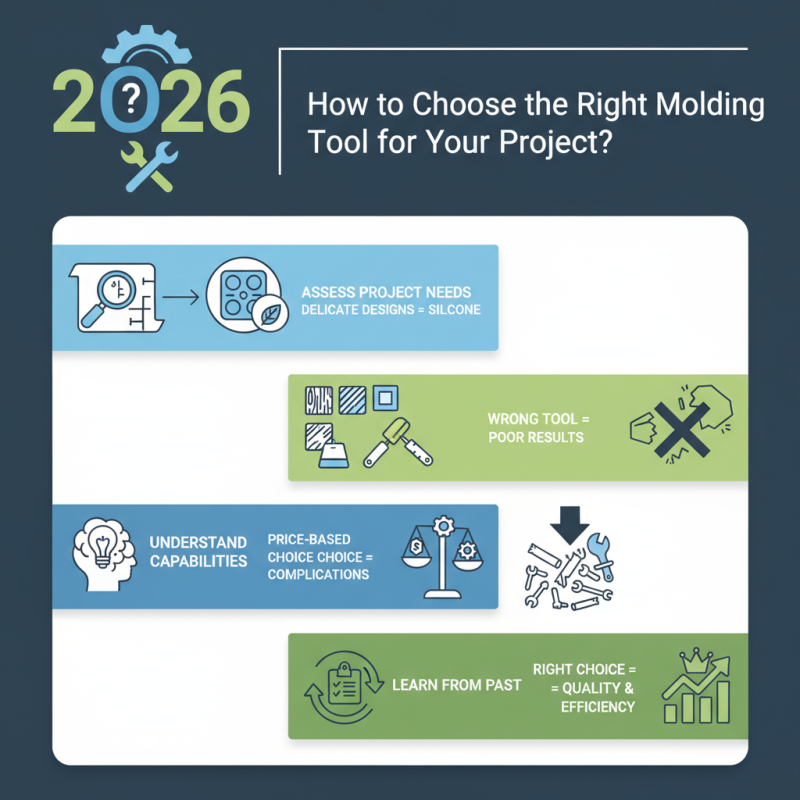

2026 How to Choose the Right Molding Tool for Your Project?

Choosing the right molding tool for your project is essential. According to John Smith, a renowned expert in the molding tool industry, "The right tool can make or break your project." This wisdom highlights the significance of careful selection.

When considering molding tools, it's crucial to assess your project's specific needs. Different materials require different tools. For example, a silicone molding tool works best for delicate designs. If you overlook this detail, your final product may not meet your expectations.

Mistakes often stem from not understanding the tool's capabilities. Some tools seem ideal but fail in practical applications. For instance, choosing a tool based on price alone can lead to complications. Reflecting on past choices can help refine your decision-making process. In the molding tool industry, the right choice enhances quality and efficiency.

Types of Molding Tools Available for Various Projects

When selecting molding tools for a project, it’s crucial to understand the variety available. Hand tools like chisels and scrapers excel in precision work. They are ideal for intricate designs. Many professionals rely on these for detailed pieces. According to industry data, over 40% of craftsmen prefer traditional hand tools for their sensory feedback and hands-on control.

Power tools also play a vital role. Routers and CNC machines offer speed and repeatability. They are perfect for larger projects requiring consistency. Recent studies show that about 60% of manufacturers opt for these tools in production settings. However, the learning curve can be steep. Misuse can lead to waste or flawed outputs. It’s essential to find a balance between efficiency and skill level.

Consider the material used. Different tools work better with wood, plastic, or metal. Each material has unique properties influencing tool selection. For instance, softer woods may not need a heavy-duty tool. Also, stay mindful of costs. Investing in high-quality tools can save money long-term. However, cheaper options may lead to frustration and performance issues. Ultimately, reflect on your specific needs and project goals.

Factors to Consider When Selecting a Molding Tool

Selecting the right molding tool for a project can be challenging. There are several factors to consider. One crucial aspect is the type of material you are working with. Different materials require specific tools. For example, softer materials may need different tools compared to harder ones. Knowing the characteristics of these materials is essential.

Another factor is the complexity of the design. Intricate designs might need advanced tools. Simpler designs could work well with more basic options. The size of the project also plays a role. Larger projects often require larger molding tools. Choose based on the scale of your work.

Additionally, comfort and ease of use should not be overlooked. A tool that feels good in your hands can make a big difference. Many users make the mistake of prioritizing price over comfort. This can lead to frustration during lengthy projects. It's important to reflect on how the tool fits your workflow. Taking time to assess these factors leads to better outcomes.

Assessing the Material Requirements for Your Molding Tool

Choosing the right molding tool is crucial for project success. One key factor to consider is the material requirements for the tool. Different materials offer distinct advantages in terms of durability and ease of use. For instance, metal molds often provide strength, while plastics are lightweight and easier to manage.

When assessing material needs, think about the project scale. Small projects might benefit from lower-cost plastic options. However, larger runs may require more robust materials. Each option comes with its own trade-offs. Metal molds might be expensive upfront but can lead to higher-quality outputs. In contrast, plastic molds could wear out faster, requiring replacements.

Think critically about your choice. Will the tool withstand the pressure and temperature required for your project? Are there environmental factors that might influence the material quality? Questions like these guide you to the right decision. Ensure your selection aligns with your project's long-term goals and resource availability. Making the wrong choice can be costly and time-consuming.

Understanding the Importance of Tool Size and Shape

Choosing the right molding tool significantly influences project outcomes. Tool size and shape can make or break your design. It’s essential to select tools that match your specific project requirements.

The American Society of Plastic Engineers highlights that improper tool size can result in a 30% increase in cycle times. This data stresses the importance of choosing the right dimensions. For example, a smaller tool may not fill well, leading to defects. Meanwhile, oversized tools can lead to excess material wastage.

**Tips:** Always assess your prototype. Testing helps gauge if the size truly fits your needs. Remember, experimenting with different shapes often reveals better results.

Additionally, consider the material type when choosing the tool shape. Complex shapes are more sensitive to material properties. Some reports note that using inappropriate shapes can increase production errors by up to 25%. Balancing shape and material can thus save time and resources.

**Tips:** Review case studies on tooling shapes and their impacts. Learning from past projects can prevent future mistakes. Checking user feedback on shaping options helps, too.

Choosing the Right Molding Tool: Size and Shape Impact

Best Practices for Maintenance and Care of Molding Tools

Molding tools are essential for precise projects. Proper maintenance is crucial to ensure their longevity. Regular cleaning is one of the best practices. Use a soft brush or cloth to remove dust and debris. This simple step prevents contamination in your work.

Inspect your tools frequently. Look for any signs of wear or damage. A small crack can lead to bigger problems. It’s tempting to overlook minor issues, but addressing them early is smart. This helps avoid costly repairs later. Lubrication is another key aspect. Use appropriate grease to keep moving parts functioning smoothly.

Storing your tools properly is vital. Keep them in a dry, dust-free environment. Moisture can cause rusting, and dust can lead to imperfections in your work. Sometimes, we may neglect these details. Reflecting on your tool care habits can reveal areas for improvement. Consider creating a maintenance schedule to reinforce good practices.

Related Posts

-

Innovative Molding Tools for Streamlined Manufacturing Processes

-

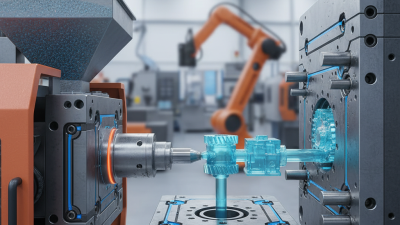

Understanding the Process: How Injection Molding Molds Shape Our Daily Products

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners

-

What is Plastic Mold Injection Machine? A Comprehensive Guide to Its Types and Applications

-

2025 Top Trends in Mold Injection Manufacturing and Market Growth Insights

-

What is the Plastic Injection Moulding Process and How Does it Work