How to Choose the Right Plastic Components for Your Project?

Choosing the right plastic components for your project is crucial. The materials you select can impact the performance, durability, and cost of your final product. Understanding the various types of plastic is a starting point. Some plastics are strong and resistant; others might be more suitable for light applications.

Consider the specific needs of your project. Is flexibility important? Or maybe heat resistance? Each plastic component offers different advantages. Familiarity with properties like tensile strength, thermal stability, and corrosion resistance is essential. Engaging with suppliers can provide insights. They often have expertise in selecting the best material.

It's easy to overlook quality in pursuit of cost savings. The wrong choice of plastic components can lead to failures. Reflecting on past projects might help avoid mistakes. Sometimes, a deeper understanding of your materials leads to better outcomes. Choosing wisely ensures your project stands the test of time.

Understanding the Types of Plastic Materials Available for Projects

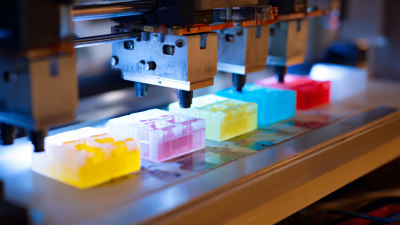

When selecting plastic materials, understanding the types available is crucial. Plastics can be broadly categorized into thermoplastics and thermosetting plastics. Thermoplastics, like polyethylene and polypropylene, are flexible and can be reshaped multiple times. This flexibility makes them a favorite for many projects. Yet, they can be prone to deformation under heat.

On the other hand, thermosetting plastics, such as epoxy and phenolic, are hardened during manufacturing. They offer higher heat resistance and durability. However, once set, they cannot be remolded. This aspect should be a key consideration for your project. Choosing the wrong type can lead to issues down the line.

Moreover, factors like strength, weight, and cost should not be overlooked. Some plastics are lightweight but may lack strength. Others might be strong but are more expensive. Balancing these traits requires careful evaluation. It’s essential to consider the specific needs of your project. Reflecting on past choices can help avoid mistakes in future selections.

Plastic Material Types and Their Applications

Evaluating the Mechanical Properties of Plastics for Your Application

When selecting plastic components, understanding mechanical properties is crucial. Different projects require varying strengths, flexibility, and resistance to impact. Some plastics excel in tensile strength, while others may offer better toughness. Knowing these properties helps in making informed choices.

Consider the application’s environment. Will the plastic be exposed to extreme temperatures? Heat-resistant plastics are essential in high-temperature applications. Low temperatures may require materials that retain flexibility, avoiding brittleness. Testing under actual conditions can reveal weaknesses that might not be apparent during initial evaluations.

Be mindful of the balance between cost and performance. Sometimes, the cheaper option may lack durability, leading to failures. It’s vital to assess long-term performance over initial savings. Revisiting material choices based on prototype testing can yield insights that enhance your project's success. Don’t overlook the importance of supplier reliability, as material variations can affect overall project outcomes.

Considering Environmental Factors and Regulations in Material Selection

When selecting plastic components for a project, environmental factors and regulations are crucial. Understanding the environmental impact of materials is essential. For example, certain plastics can release harmful chemicals during production or disposal. Always consider the end-of-life implications, including recycling and biodegradability.

Tips: Check local regulations. Some areas may have restrictions on specific plastics. Knowing these rules can save time and prevent project delays. Investigate sustainable options, like bioplastics, which have less environmental impact. They’re not always the best choice, though; understand your project needs.

Choosing the right material is often challenging. Not every plastic type complies with environmental standards. Testing your components is vital. Sometimes, the first choice isn’t the best choice. An unexpected result can lead to costly adjustments. Prioritize materials that align with both functionality and environmental responsibility. Assess risks honestly. Learn from any missteps to improve future decisions.

Assessing Cost-Effectiveness and Availability of Plastic Components

When selecting plastic components for your project, cost-effectiveness and availability are critical factors. Start by researching various types of plastics. Some materials are readily available, while others can have long lead times. This availability impacts your project timeline.

Cost-effectiveness is not merely about choosing the cheapest option. Evaluate the material's durability, functionality, and long-term performance. Sometimes, cheaper options may lead to higher replacement costs later. It's essential to balance initial costs with potential future expenses. Quality often outweighs short-term savings.

Although there are many choices, not all of them are suitable. Sometimes, the best material may not be in stock. Re-evaluating your options can lead to unexpected discoveries. Keep an open mind; adapting your design may yield better results. Consider pilot testing to gauge performance and cost before committing fully. This step can save time and resources in the long run.

Making Informed Choices: Supplier Reliability and Quality Assurance

When selecting plastic components, the reliability of your supplier plays a critical role. A thorough check of their history is essential. Look for suppliers with a solid reputation in the industry. Gather reviews and testimonials from previous clients. This step often reveals valuable insights into their consistency and reliability.

Quality assurance is another key factor. Ensure that the supplier adheres to strict manufacturing standards. Request documentation that demonstrates their commitment to quality. This might include certifications or results from third-party testing. Sometimes, suppliers may offer these voluntarily, but it's also fine to ask directly. Pay attention to any red flags that arise during these conversations.

It's important to remember that not every supplier is perfect. Some may have minor lapses in quality or delivery times. Consider discussing these issues openly with them. This will help establish a transparent communication channel. Transparency fosters a better working relationship. The goal is to mitigate risks while choosing the right components for your project.

How to Choose the Right Plastic Components for Your Project?

| Material Type | Common Applications | Durability | Cost (per kg) | Supplier Reliability Rating |

|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Consumer products, automotive parts | Moderate | $2.00 | 4/5 |

| PVC (Polyvinyl Chloride) | Pipes, fittings, siding | High | $1.50 | 4.5/5 |

| Polyethylene (PE) | Bottles, containers, toys | Moderate to High | $1.20 | 4.2/5 |

| Polycarbonate (PC) | Lenses, safety equipment | Very High | $3.00 | 4.8/5 |

| Nylon (PA) | Gears, bearings, automotive | High | $2.50 | 4.6/5 |

Related Posts

-

Exploring Innovations in Plastic Manufacturing: Sustainable Solutions for Tomorrow

-

Top 5 Benefits of Using Prototype Plastic Molding for Your Product Development

-

Top 10 Benefits of Mold Injection for Effective Product Manufacturing

-

2025 Top Trends in Mold Injection Manufacturing and Market Growth Insights

-

Top 10 Plastic Injection Molded Parts You Need to Know for Your Business

-

Top 10 Benefits of Plastic Injection Moulding Process?