How to Choose the Right Injection Molding Tooling for Your Project

In the realm of manufacturing, specifically in the plastics industry, injection molding tooling serves as a critical component that directly influences product design, production efficiency, and overall costs. According to a report by Grand View Research, the global injection molding market size was valued at USD 223.55 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 3.6% from 2021 to 2028. A well-chosen injection molding tooling can enhance production cycles, reduce waste, and lead to higher quality outcomes, ultimately affecting the profitability of a project.

Choosing the right injection molding tooling requires a comprehensive understanding of various factors, including material selection, part geometry, tolerances, and desired production volume. Missteps in tooling selection can lead to increased lead times, higher costs, and compromised quality, which may jeopardize project timelines and client satisfaction. As highlighted by the American Society of Mechanical Engineers, up to 70% of product design issues can be traced back to tooling decisions, underscoring the essential role that proper tooling plays in successful manufacturing outcomes. Thus, understanding the complexities and nuances of injection molding tooling is vital for businesses aiming to optimize their production processes and remain competitive in a fast-evolving market.

Understanding Injection Molding Tooling: Key Concepts and Terminology

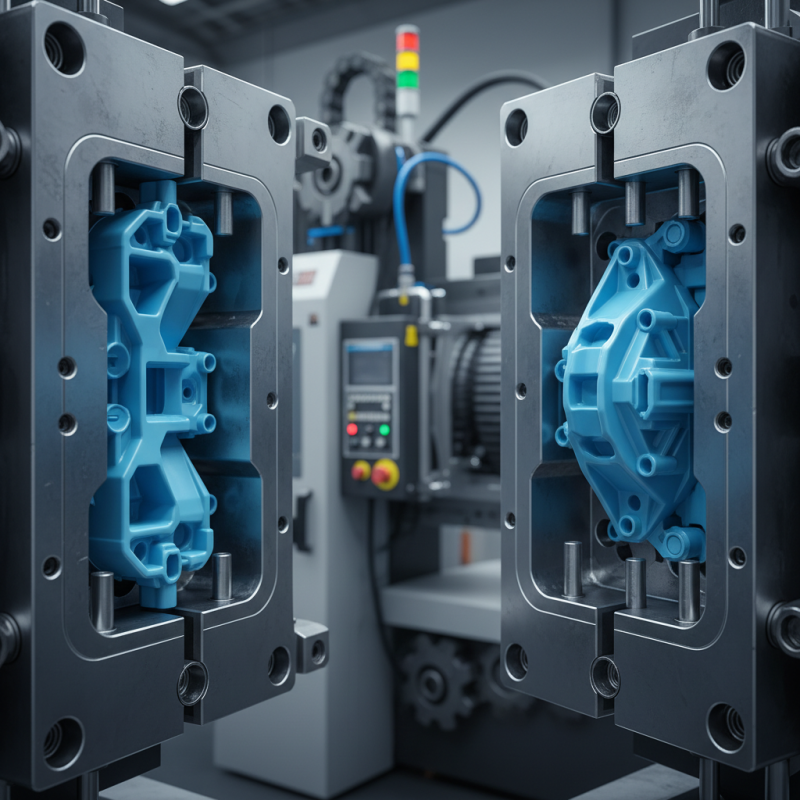

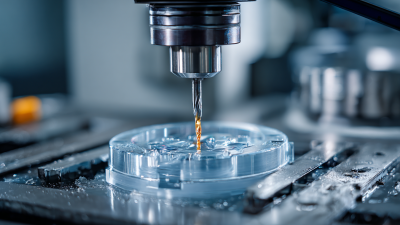

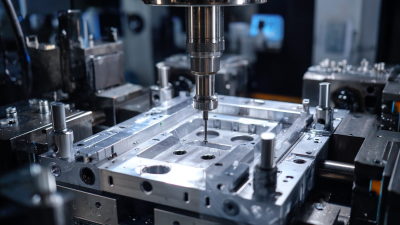

Injection molding is a widely used manufacturing process that requires an understanding of various tooling concepts and terminology to ensure a successful project. At the heart of injection molding tooling is the mold itself, which serves as the cavity where the molten material is injected to form parts. The design of the mold, including its geometry, cooling channels, and ejection systems, plays a crucial role in determining the quality and precision of the final product. It is essential to understand terms like "core," "cavity," and "parting line." as they define the mold's structure and functionality.

Another important aspect of injection molding tooling is material selection. The choice of tooling material influences durability, production speed, and the cost of the project. Common tooling materials include steel and aluminum, each offering unique benefits depending on the project’s requirements, such as the expected production volume and part complexity. Additionally, familiarity with concepts like "draft angle" and "tolerance" is vital, as these elements impact the manufacturing process and the ease of part removal from the mold. A solid grasp of these key concepts and terminology will aid in the selection of the right injection molding tooling, ensuring optimal results for any project.

Factors to Consider When Selecting Injection Molding Tooling

When selecting injection molding tooling for your project, several critical factors must be considered to ensure that the final product meets your specifications and industry standards. First, assess the complexity of the part design. Intricate geometries and tight tolerances may necessitate advanced tooling solutions, such as multi-cavity molds or core-pulling mechanisms. The material properties of the plastic being molded also play a vital role; different resins may require specific tooling surface finishes and temperature control features to achieve optimal flow and minimize defects.

Another important aspect to consider is the volume of production you anticipate. If your project demands high production rates, investing in high-quality, durable tooling may be essential to withstand wear over time, ultimately resulting in lower costs per part. Conversely, for lower volume runs, opting for cost-effective tooling options could be more advantageous. Additionally, think about the lead time required for production and how that affects your project timeline. Balancing these factors will help you make an informed decision in choosing the right injection molding tooling that aligns with your project goals.

Types of Injection Molding Tools and Their Applications

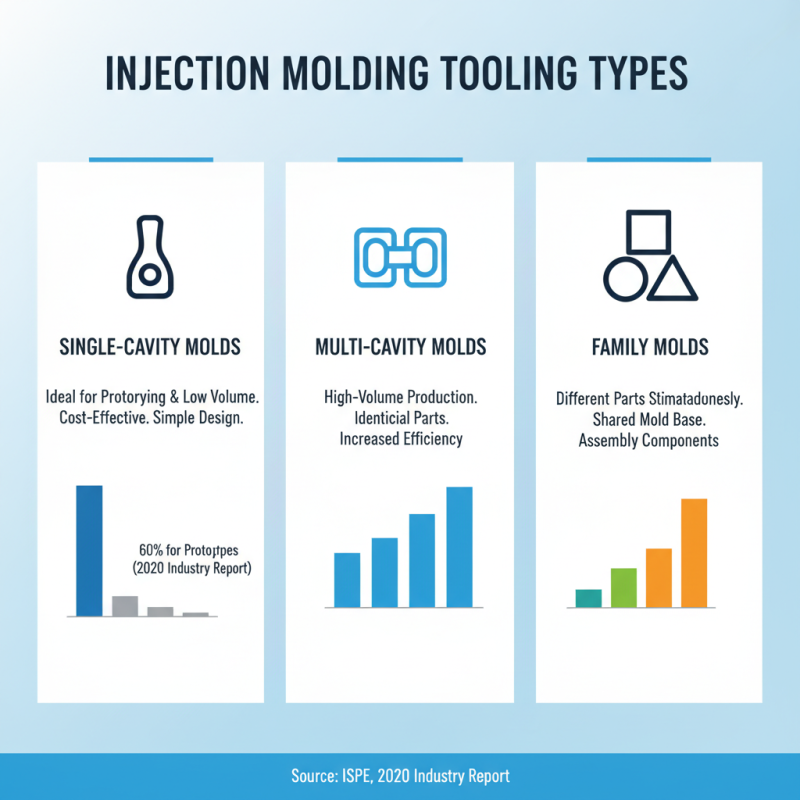

Injection molding is a crucial manufacturing process utilized across various industries, and selecting the right tooling is critical for project success. The primary types of injection molding tools include single-cavity molds, multi-cavity molds, and family molds, each tailored for different production needs and efficiencies. Single-cavity molds are ideal for low-volume production runs, offering simplicity and cost-effectiveness. According to a 2020 industry report by the International Society of Plastics Engineers, approximately 60% of companies prefer single-cavity molds for prototyping and initial runs due to their lower upfront costs.

In contrast, multi-cavity molds increase production efficiency by allowing several identical parts to be produced simultaneously. This type is essential for high-volume manufacturing, with a noted capability to reduce cycle times significantly. Data from a recent study by the Plastics Industry Association indicates that transitioning to multi-cavity molds can enhance productivity by up to 40%, making them a preferred choice for manufacturers aiming to meet high demand. Family molds, which allow for different parts to be produced in one cycle, are particularly beneficial in industries needing varied components but maintaining cost-effectiveness and production efficiency. Choosing the appropriate tooling not only impacts production costs but also influences timelines and overall project outcomes.

Evaluating Material Compatibility for Injection Molding Tooling

When selecting injection molding tooling for your project, evaluating material compatibility plays a crucial role in ensuring optimal performance and efficacy. The choice of material not only influences the quality of the final product but also affects production efficiency and cost. According to a report from the American Society for Testing and Materials (ASTM), over 70% of production issues stem from material incompatibility. This highlights the importance of understanding the properties of both the tooling material and the plastic resin used in the molding process.

Different resins have unique characteristics such as melting temperature, viscosity, and chemical resistance, which can significantly impact tooling design and longevity. For instance, materials like polycarbonate require tooling that can withstand higher temperatures compared to more standard solutions. Industry reports suggest that mismatched tooling materials can result in extensive downtime, with an average cost exceeding $100,000 per incident, emphasizing the need for careful selection. Additionally, investing in materials with enhanced thermal conductivity can improve cycle times and overall productivity, offering a substantial return on investment for manufacturers looking to optimize their processes.

Cost Analysis and Budgeting for Injection Molding Tooling Projects

When embarking on an injection molding project, understanding the cost implications of tooling is paramount. The budget for tooling can significantly impact the overall project cost, and careful planning is essential. Several factors contribute to the expenses incurred in injection molding tooling, including material selection, design complexity, and the need for precision in manufacturing. A well-considered budget should account for both initial costs and ongoing maintenance expenses, ensuring that all financial aspects are transparent and anticipated.

Cost analysis begins with assessing the project requirements and production volume. Low to medium production runs may benefit from less intricate tooling, which can reduce upfront costs. As the expected production volume increases, investing in high-quality tooling becomes justifiable, as it can lead to lower per-unit costs and improved product consistency over time. Additionally, it is crucial to factor in lead times and potential delays in the budgeting process, as these can further affect project costs. By carefully evaluating these variables, project managers can make informed decisions that align quality with budget constraints, ultimately ensuring a successful injection molding endeavor.

Related Posts

-

Exploring Innovative Molding Solutions: Transforming Ideas into Reality Through Advanced Techniques

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency

-

Top 10 Benefits of Mold Injection for Effective Product Manufacturing

-

What is Plastic Mold Injection Machine? A Comprehensive Guide to Its Types and Applications

-

2025 Top Plastic Injection Molded Parts: Innovations and Market Trends

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products