How to Choose the Right Injection Molding Tooling for Your Project

In the realm of manufacturing, selecting the appropriate injection molding tooling is a pivotal decision that can significantly influence the success of a project. According to industry reports by the Plastic Industry Association, the injection molding process accounts for over 30% of plastic part production in the United States, underscoring its critical role in the overall manufacturing landscape. As the demand for precision and efficiency in production increases, understanding the intricacies of injection molding tooling becomes essential for engineers and project managers alike.

Expert insights highlight the importance of this decision. Dr. Michael C. F. Wu, a renowned authority in the field of polymer engineering, emphasizes that "Choosing the right injection molding tooling is not just about cost; it’s about optimizing performance and ensuring the longevity of the molds." This perspective resonates with the growing complexity of product designs and the advancing technologies in molding processes, which require tailored tooling solutions to achieve high-quality outputs while minimizing waste and downtime.

As industries evolve, the challenges of selecting injection molding tooling that meets specific project requirements—such as material compatibility, mold complexity, and production volume—are more pronounced. Therefore, making informed decisions rooted in both data and expert insights remains paramount for achieving successful project outcomes in an increasingly competitive market.

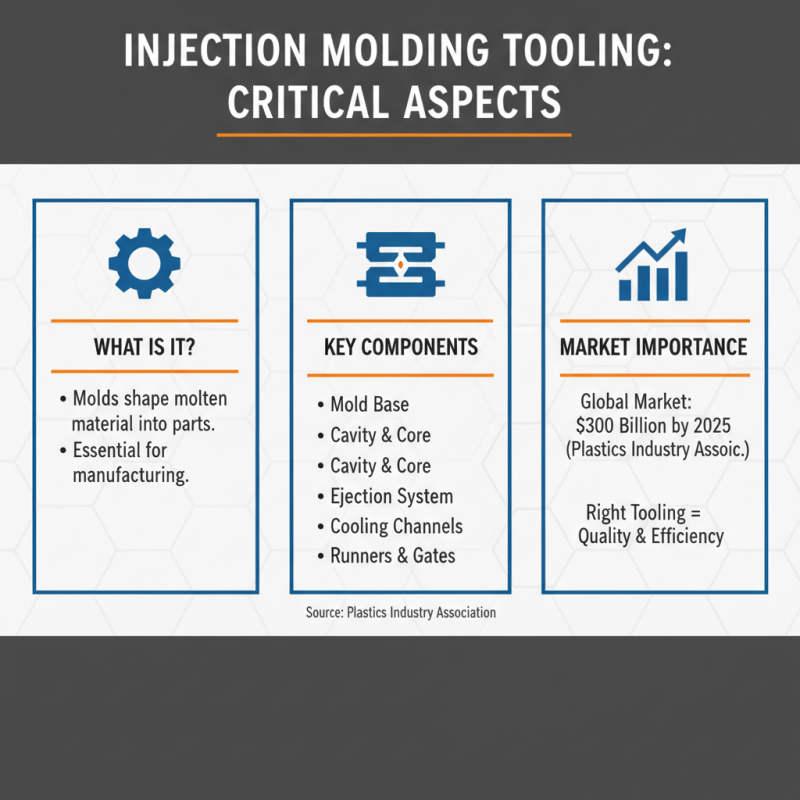

Understanding Injection Molding Tooling: Key Concepts and Terminology

Injection molding tooling is a critical aspect of the manufacturing process, involving various components and intricate terminology that can significantly impact your project's success. At its core, tooling refers to the molds used to shape molten material into solid parts; understanding the nuances of this term is essential for any project developer. According to data from the Plastics Industry Association, the global injection molding market is projected to reach $300 billion by 2025, highlighting the importance of choosing the right tooling to ensure quality and efficiency in production.

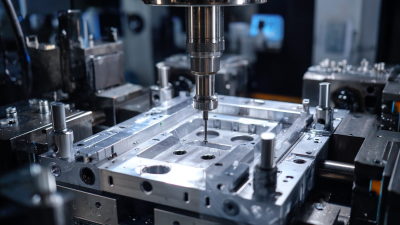

When selecting tooling, it’s vital to consider factors such as material selection, mold design, and production volume. For instance, steel molds offer durability and precision, making them suitable for high-volume production, while aluminum molds are often preferred for shorter runs due to lower cost and faster turnaround times. Understanding the terminology related to these materials—such as "inserts," "draft angles," and "tooling costs"—can help streamline the decision-making process.

**Tips:** Always assess the projected production quantities early on. If your project requires rapid prototyping, consider using modular tooling, which can adapt to design changes without significant additional costs. Additionally, collaborating with experienced tooling engineers can provide insights into optimizing both the design and material choices tailored to your specific application.

Assessing Project Requirements: Volume, Material, and Design Considerations

When choosing the right injection molding tooling for your project, understanding the specific requirements of volume, material, and design is crucial. First and foremost, the project’s production volume significantly influences the type of tooling you should select. High-volume production typically demands durable tooling that supports faster cycle times and can withstand repeated use without failure. In contrast, low to medium volumes may allow for more cost-effective tooling solutions, such as aluminum molds, which can be less expensive and quicker to produce but may not offer the same longevity.

Material selection is another critical factor, as different materials exhibit varying properties that can affect both the mold and the final product. For example, thermoplastics may require different mold designs and materials compared to thermosets. Understanding the thermal and mechanical properties of the materials used will inform decisions about cooling channels, mold surface finishes, and overall design intricacies. Additionally, collaborate closely with engineers and designers to ensure that the chosen materials align with the desired product characteristics, such as strength, flexibility, and appearance, while also being suitable for the selected tooling approach.

Design considerations cannot be overlooked either. The geometry and complexity of the part play a vital role in determining the tooling method. Intricate designs may need advanced tooling techniques that can accommodate undercuts and thin walls, while simpler shapes might permit more traditional approaches. Ensuring that the design is optimized for injection molding can result in smoother production processes and reduce the risk of defects in the final products. Properly balancing these factors will lead to an efficient and successful injection molding process tailored to your project needs.

Injection Molding Tooling Requirements

Evaluating Different Types of Injection Molding Tools and Their Applications

When selecting the right injection molding tooling for your project, understanding the various types of tools available is crucial. The most common types include single-cavity and multi-cavity molds.

Single-cavity molds are ideal for projects that require low to moderate production volumes and offer the advantage of simplicity in design and lower costs. These molds are particularly useful when prototyping or testing product viability, allowing for faster iterations without substantial financial investment.

On the other hand, multi-cavity molds are designed to produce multiple parts with each cycle, significantly increasing production efficiency. This type of tooling is more suitable for high-volume manufacturing where consistency and speed are paramount. However, they come with a higher upfront cost and complexity in design and maintenance.

Another consideration is the type of material you plan to use, as certain molds can provide better compatibility with specific polymers or composites, thereby influencing your choice. Ultimately, evaluating these different types of injection molding tools based on your project’s specific needs will help in achieving optimal results.

Cost Analysis: Balancing Quality and Budget Constraints for Tooling

When it comes to injection molding tooling, balancing quality and budget can be a challenging task. On one hand, you want to invest in high-quality tools that ensure precision and durability; on the other hand, your project budget may restrict your options. The key is to conduct a thorough cost analysis while considering the entire lifecycle of the tooling. This includes initial costs, maintenance, and potential downtime due to tool failure. Prioritizing durability and efficiency can lead to better long-term investments, reducing the need for frequent replacements.

Tips for cost-effective tooling decisions include opting for standardized components whenever possible. Standard tools can be more readily available and often come at a lower cost than custom solutions. Additionally, it's helpful to collaborate closely with your tooling supplier to explore options for cost savings without sacrificing quality. Effective communication might reveal less expensive materials or alternate designs that fulfill your project requirements while remaining within budget constraints.

Another aspect to consider is the total production volume. If you anticipate high demand, investing in higher-quality tooling may pay off. Conversely, for lower volume projects, it may be more prudent to choose tools with a balance of quality that fits within your immediate budget. Always evaluate the trade-offs between quality and cost to ensure that your choice aligns with your project goals.

Selecting a Reliable Tooling Partner: What to Look For in a Manufacturer

Selecting a reliable tooling partner is crucial for the success of any injection molding project. When choosing a manufacturer, first assess their experience and qualifications in the industry. Look for partners who have a proven track record in producing high-quality tooling that meets specific client requirements. A well-established manufacturer will not only have the necessary technical expertise but also the capacity to handle projects of varying complexities and scales.

Tips: Always request case studies or references from potential tooling partners. This will give you insights into their past projects and customer satisfaction. Moreover, consider their communication style and responsiveness during the initial discussions, as this can be indicative of the level of support you can expect throughout the project.

Additionally, evaluate the manufacturer’s capacity for innovation and technology adoption. A partner that invests in the latest technologies will be better equipped to offer advanced solutions that enhance efficiency and reduce lead times. Discuss their approach to quality control and ensure they have rigorous testing protocols in place to assure the durability and performance of the tooling produced.

Tips: Take note of the tooling partner's willingness to collaborate and adapt to your project changes. This flexibility can save time and resources in the long run, ensuring that your project remains on schedule and meets the desired specifications.

Related Posts

-

Top 5 Tips for Optimizing Injection Molding Tooling Efficiency

-

Top 10 Benefits of Mold Injection for Effective Product Manufacturing

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners

-

How Injection Mold Manufacturing is Revolutionizing Product Development in 2023