Top 10 Best Practices for Plastic Injection Mold Design?

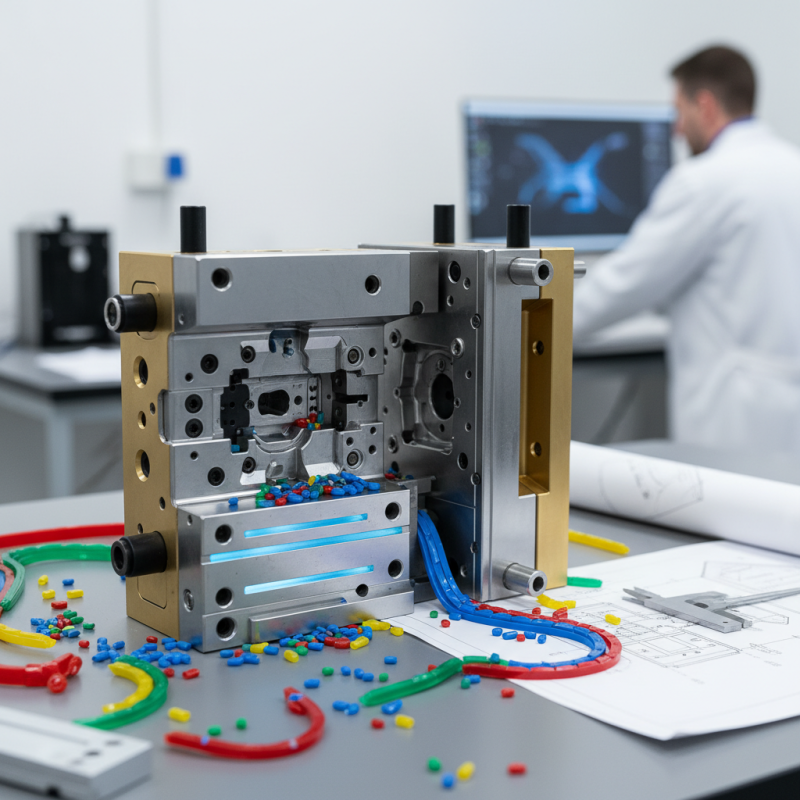

In the world of plastic injection mold design, precision is paramount. Renowned expert Dr. Jane Smith emphasizes, "Quality molds lead to quality products." This highlights the importance of effective mold design. A well-designed mold can reduce defects and optimize production efficiency.

Many designers still struggle with common pitfalls. Often, they overlook cooling channel placement and material selection. These missteps can lead to increased cycle times and higher costs. Not every design meets the required standards. Some designers fail to incorporate sufficient feedback loops for improvements, leading to repeated mistakes.

Adopting best practices in plastic injection mold design is crucial. It requires attention to detail and a willingness to learn from previous experiences. Designers must balance creativity with engineering principles. Continuous learning and adaptation are essential in this field. Embracing these challenges can ultimately enhance product quality and manufacturing efficiency.

Understanding the Importance of Plastic Injection Mold Design

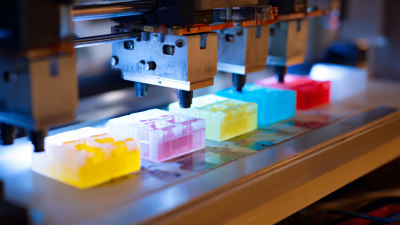

Plastic injection mold design plays a critical role in manufacturing. It directly impacts product quality, cost, and production efficiency. A well-designed mold can improve the production rate and reduce cycle times. Yet, many overlook its importance. Design flaws can lead to significant setbacks.

Understanding the nuances of mold design is essential. Mold flow analysis can reveal potential issues before production begins. This analysis helps in identifying areas prone to defects like warping or incomplete filling. Small design adjustments might seem trivial but can yield enormous benefits. Even experienced designers can miss subtle problems that require reflection and correction.

Mold maintenance also matters greatly. Regular inspections can prevent costly repairs. Ignoring wear and tear can compromise product integrity. Designers must consider long-term use and potential wear patterns. Recognizing these factors early fosters a more sustainable production process. Ultimately, a thoughtful approach to mold design enhances overall manufacturing performance.

Top 10 Best Practices for Plastic Injection Mold Design

This chart illustrates the relative importance of various best practices for plastic injection mold design, rated on a scale from 1 to 10. Proper implementation of these practices can significantly affect the quality and efficiency of the injection molding process.

Key Factors Influencing Mold Design Efficiency

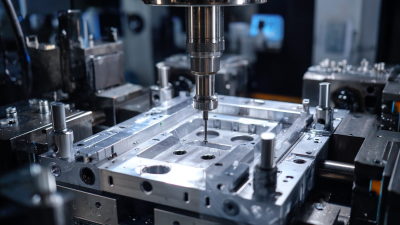

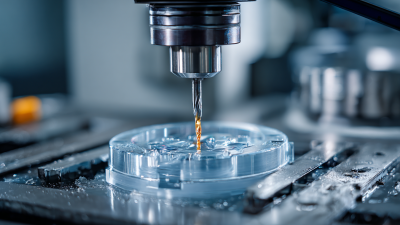

When designing a plastic injection mold, key factors significantly influence efficiency. One important aspect is material choice. Using appropriate materials based on the part's function can save time and costs. Consider how the material flows during the injection process. It plays a crucial role in achieving uniform cooling and reducing defects.

Tips: Always test different materials. Each choice affects the final product's quality. Be ready to modify designs based on test results. Sometimes, these adjustments can lead to unexpected improvements.

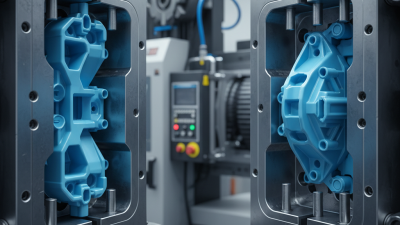

Another factor is the mold's geometry. Clever design minimizes complexity. A simpler mold often reduces production time. However, it also can lead to limitations in design intricacies. Balancing detail and efficiency is a common struggle in mold design.

Tips: Use computer simulations to predict performance. This can save resources and provide insights before physical prototypes are made. Evaluate every design step to ensure it meets production goals. Reflect on past projects to learn from previous mistakes.

Top 10 Best Practices for Plastic Injection Mold Design

| Practice | Description | Key Benefit | Impact on Efficiency |

|---|---|---|---|

| Material Selection | Choosing the right plastic material based on properties and application. | Improved product quality and performance. | High |

| Draft Angles | Incorporating draft angles to facilitate part removal from the mold. | Reduced cycle time and easier demolding. | Medium |

| Cooling System Design | Optimizing the cooling channels for better thermoregulation. | Lower cycle times and reduced energy usage. | High |

| Part Design | Designing parts with uniform wall thickness to minimize defects. | Fewer warpage and sink marks. | High |

| Mold Flow Analysis | Simulating the injection process to predict flow characteristics. | Identifies potential issues before production. | Medium |

| Surface Finish | Choosing appropriate surface texture for appearance and functionality. | Enhanced aesthetics and user satisfaction. | Medium |

| Vent Design | Including vents to allow air to escape during injection. | Reduction of defects related to trapped air. | Medium |

| Tooling Material | Selecting durable materials for mold construction. | Longer mold life and consistent part quality. | High |

| Pilot Runs | Conducting initial trials to troubleshoot and refine the mold. | Identifying issues early to save time and costs. | High |

Common Design Pitfalls and How to Avoid Them

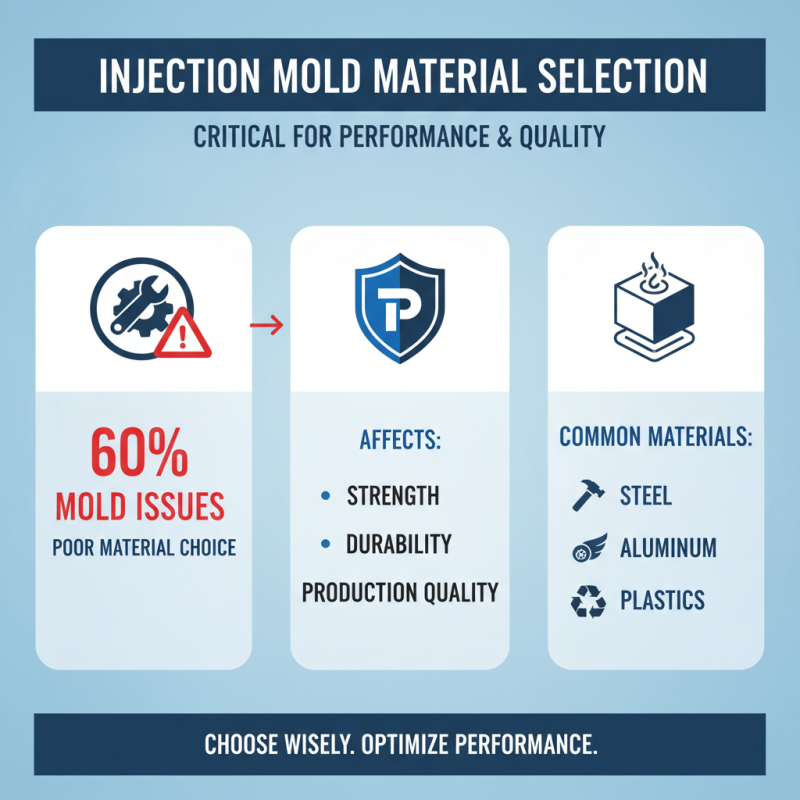

When designing plastic injection molds, common pitfalls can lead to costly delays and defects. Many designers overlook the importance of material selection. For instance, using the wrong resin can cause warping or insufficient strength.

A recent study showed that up to 40% of mold defects stem from improper material choices. Understanding the material properties is crucial.

Another frequent mistake is neglecting the draft angle. Inadequate draft can result in part sticking to the mold, complicating ejection. Designers often forget that a simple 2-5 degree angle can significantly ease this process. The costs of reworking molds due to inadequate drafts can soar.

Lastly, underestimating cooling times can lead to longer cycle times, affecting production efficiency. Research indicates that poor cooling channel design can increase cycle times by 20-30%. This inefficiency can hamper overall production schedules.

Material Selection Considerations for Injection Molds

When designing injection molds, material selection plays a crucial role. Plastics engineers estimate that nearly 60% of mold performance issues stem from poor material choices. Selecting the right material affects strength, durability, and overall production quality. Common choices include steel, aluminum, and various plastic formulations. Each material has unique properties that dictate its suitability for specific applications.

For instance, steel molds are popular for their longevity, typically lasting for thousands of cycles. However, they are often more expensive and take longer to manufacture. In contrast, aluminum molds are lighter and cheaper, perfect for low to medium production runs. Yet, they wear out faster. The market survey indicates that around 45% of manufacturers still use traditional materials, despite advances in composites and specialty materials. This reluctance to adapt can lead to missed opportunities for efficiency improvements.

Choosing the wrong material can result in defects and increased costs. Many engineers overlook the impact of temperature resistance on material choice. High-temperature materials provide better performance but might not fit every budget. In some cases, it’s essential to evaluate long-term versus short-term needs. By understanding these factors, designers can avoid common pitfalls and better align material choices with production goals.

Best Practices for Maintenance and Longevity of Injection Molds

Maintaining the longevity of injection molds is critical for efficient production. Regular maintenance can reduce downtime significantly. An industry report suggests that 30% of mold failures are due to improper care. This highlights the importance of establishing a maintenance routine.

Routine inspections can identify issues before they escalate. Key areas to check include wear on gating systems and alignment of mold components. Consider implementing a checklist for each inspection. This can ensure all aspects are covered. A simple tip: keep molds clean and dry to prevent rust and corrosion.

Another aspect to consider is lubrication. Proper lubrication can significantly extend the life of moving parts. Use the recommended lubricants and apply them regularly. Interestingly, many maintenance programs overlook this step. It's crucial to document each maintenance activity. Data-driven maintenance can lead to improved reliability and reduced costs.

Related Posts

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency

-

Exploring Innovative Molding Solutions: Transforming Ideas into Reality Through Advanced Techniques

-

Top 5 Benefits of Using Prototype Plastic Molding for Your Product Development

-

Top 10 Benefits of Mold Injection for Effective Product Manufacturing

-

How to Choose the Right Injection Molding Tooling for Your Project

-

2025 How to Optimize Mold Manufacturing Processes for Increased Efficiency