Top 10 Benefits of Plastic Injection Moulding Process?

The plastic injection moulding process is a cornerstone of the manufacturing industry. This technique has revolutionized the production of plastic parts across various sectors. According to the Plastics Industry Association, the global plastic injection molding market was valued at approximately $234 billion in 2020. This figure is projected to grow, underscoring the process's critical role.

Engaging in the plastic injection moulding process offers numerous advantages. It allows for high-volume production, ensuring efficiency and cost-effectiveness. For instance, manufacturers can produce thousands of identical parts within a short time frame. Moreover, this method provides design flexibility, making it easier to create complex shapes. However, companies must remain aware of potential challenges, such as material waste and upfront costs.

While many benefits exist, there are areas for improvement. Issues like production delays or quality control can undermine efficiency. A closer look at operational practices can lead to better outcomes. Understanding both the merits and challenges of the plastic injection moulding process is vital for manufacturers looking to enhance their production strategies.

Benefits of Plastic Injection Moulding for Mass Production Efficiency

The plastic injection moulding process offers significant advantages for mass production efficiency. This method allows for high-volume manufacturing with minimal waste. Production can quickly ramp up, making it ideal for large-scale projects. Complex designs can be achieved easily, which traditional methods may struggle to replicate. Additionally, the consistency in product quality is noteworthy. Each piece produced is nearly identical, reducing the need for extensive quality checks.

The versatility of plastic injection moulding plays a critical role in its appeal. Various materials can be used, accommodating diverse industry needs. However, the initial setup costs can be high. Companies must weigh these costs against the long-term benefits. Adapting designs later in the process may also prove challenging. The complexity can lead to delays if changes are necessary. Despite these drawbacks, many still find the advantages far outweigh the risks, making it a popular choice for many manufacturers.

Cost-Effectiveness of Plastic Injection Moulding in Manufacturing Processes

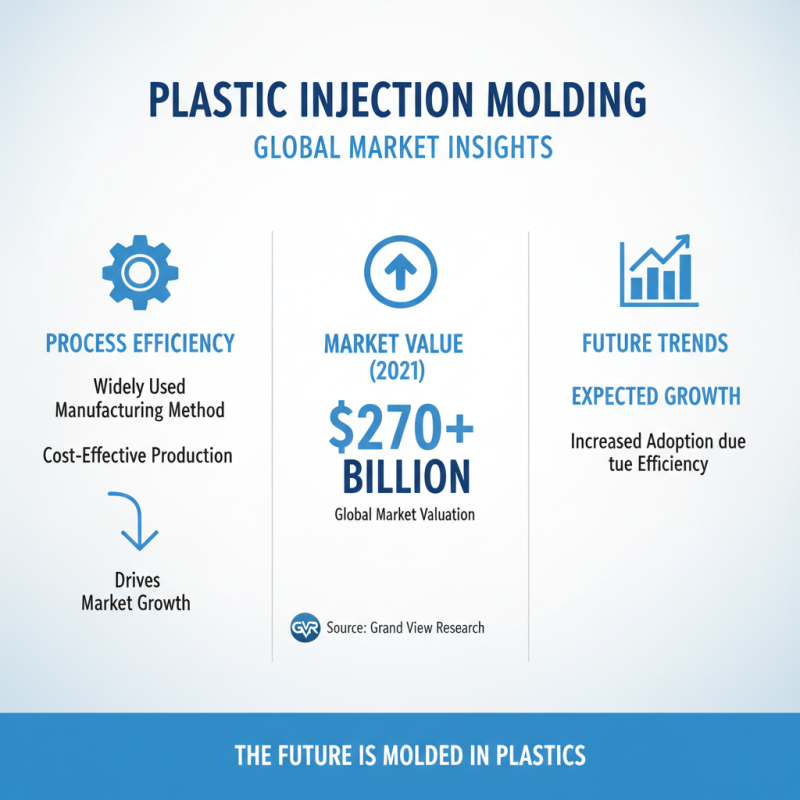

Plastic injection moulding is a widely used manufacturing process. It offers significant cost-effectiveness. According to a report by Grand View Research, the global market for injection moulding was valued at over $270 billion in 2021, with expected growth due to its efficiency.

One key advantage is the low production cost per unit. Once the initial mould is created, producing additional parts becomes inexpensive. This can lead to reduced costs by up to 50% for large production runs. However, the upfront investment for mould creation can be a barrier for smaller companies. Balancing these costs is crucial.

Material waste is also a concern. While injection moulding can minimize waste compared to other methods, it isn't perfect. Estimates show around 20% of materials may be trimmed or discarded. Companies must find ways to recycle or repurpose this excess. Ultimately, while injection moulding is cost-effective, companies should continually assess the cost-benefit ratio to maximize profits and sustainability.

High Precision and Quality Control in Injection Moulded Products

The injection moulding process is renowned for its high precision. According to recent industry reports, parts manufactured through injection moulding have tolerances as tight as ±0.001 inches. This level of accuracy is vital for industries requiring intricate components, such as aerospace and automotive sectors. The consistency in part quality leads to reduced waste and lower costs for manufacturers. In fact, the process can improve production efficiency by up to 80%.

Tip: Collaborate with experienced engineers to optimize designs for injection moulding. This can further enhance the precision of the final product.

Quality control is another crucial aspect of the injection moulding process. Automated systems monitor the production line, ensuring uniformity across batches. Reports indicate that defects in injection-moulded parts can be reduced to less than 1%. This impressive quality assurance leads to increased customer satisfaction and loyalty.

Tip: Implement regular quality audits on production processes to identify potential areas for improvement.

Despite these advantages, certain challenges remain. Factors such as material selection and machine calibration can impact quality. Manufacturers must be vigilant in maintaining equipment. Continuous training for the workforce can also help in reducing errors during production.

Environmental Sustainability in Plastic Injection Moulding Techniques

The plastic injection moulding process has made strides in environmental sustainability. Traditionally, plastic production has been associated with high energy consumption and waste. However, advancements are changing this narrative. A 2021 report by the Plastics Industry Association highlighted that modern injection moulding technologies can reduce energy use by up to 30%. This shift is not merely a trend; it reflects a growing commitment to eco-friendly practices.

Recycling is a key focus in this process. Materials used in injection moulding can often be recycled, helping to minimize landfill waste. According to the American Chemistry Council, about 9% of plastic gets recycled. This statistic underscores the need for improvement. New techniques in injection moulding are aiming to increase this percentage. Biodegradable materials are also gaining traction. They can be incorporated into injection moulding, offering alternatives that break down more easily, which is crucial for reducing environmental impact.

Despite progress, challenges remain. The industry still faces criticism over the disposal of non-recyclable plastics. Transitioning to a fully sustainable plastic manufacturing process demands adaptability. Innovators are exploring possibilities, yet the path is complex. As companies embrace eco-friendly practices, ongoing evaluation will be vital to ensure these solutions meet environmental goals effectively.

Top 10 Benefits of Plastic Injection Moulding Process

This chart illustrates the top 10 benefits of the plastic injection moulding process scored on a scale from 1 to 10. Each benefit highlights why this manufacturing technique is favored in various industries, focusing on its efficiency, design capabilities, and environmental advantages.

Versatility of Materials and Applications in Injection Moulding Process

The versatility of materials in the injection moulding process is remarkable. It accommodates a wide range of polymers, from thermoplastics to thermosets. This flexibility allows designers to choose materials based on specific properties, like durability and flexibility. For example, nylon is ideal for high-strength applications, while polyethylene is great for low-cost production.

Applications of injection moulding are equally diverse. It is used in automotive components, household items, and medical devices. The process allows for intricate designs that traditional methods may not achieve. However, not every product benefits from injection moulding. Some designs may be too complex, leading to high costs and wasted materials.

The need for careful design remains essential. Over-engineering can lead to inefficiency. It is crucial to balance material choice and design simplicity. Reflecting on this can guide better decisions in future projects. It’s a fine line between creativity and practicality in the injection moulding field.

Top 10 Benefits of Plastic Injection Moulding Process

| Benefit | Description | Applications |

|---|---|---|

| High Efficiency | Allows for rapid production cycles, reducing time and costs. | Mass production of plastic parts for automotive and consumer products. |

| Complex Shapes | Enables creation of intricate designs that would be difficult or impossible with other methods. | Electronics housings, toys, and medical devices. |

| Material Versatility | Compatible with a wide range of thermoplastic materials. | Packaging, consumer products, and automotive components. |

| Low Waste | Minimizes excess material usage, enhancing sustainability. | Parts production for various industries with reduced scrap. |

| High Strength | Parts can be made stronger through the right material selection and design. | Industrial applications and heavy-duty containers. |

| Cost-Effective for Large Runs | Economical when producing large quantities of parts. | Automotive parts and home appliances. |

| Consistency and Quality Control | Provides high levels of precision and repeatability. | Consumer electronics and precision components. |

| Enhanced Surface Finish | Can produce parts with a smooth surface finish suitable for various applications. | Auto parts, decorative items, and kitchenware. |

| Quick Prototyping | Allows for rapid creation of prototypes for testing and design validation. | Product design and engineering trials. |

| Good for Various Industries | Used in automotive, medical, consumer goods, and more. | Cross-industry applications, enhancing versatility. |

Related Posts

-

2025 Top Trends in Mold Injection Manufacturing and Market Growth Insights

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners

-

Top 10 Benefits of Mold Injection for Effective Product Manufacturing

-

Top 5 Tips for Optimizing Injection Molding Tooling Efficiency

-

Top Mold Injection Techniques for Efficient Manufacturing in 2025

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products