2025 Top Trends in Mold Injection Manufacturing and Market Growth Insights

As we look ahead to 2025, the mold injection manufacturing industry is poised for significant transformation driven by technological advancements and evolving market demands. Mold injection, a process fundamental to producing a wide range of plastic products, has witnessed a remarkable shift in its methodologies and applications. According to a recent report by MarketsandMarkets, the global mold injection market is projected to reach USD 313.9 billion by 2025, growing at a CAGR of 4.5% from 2020. This growth is attributed to increasing demand in key sectors such as automotive, consumer goods, and healthcare, where precision manufacturing and rapid prototyping are critical.

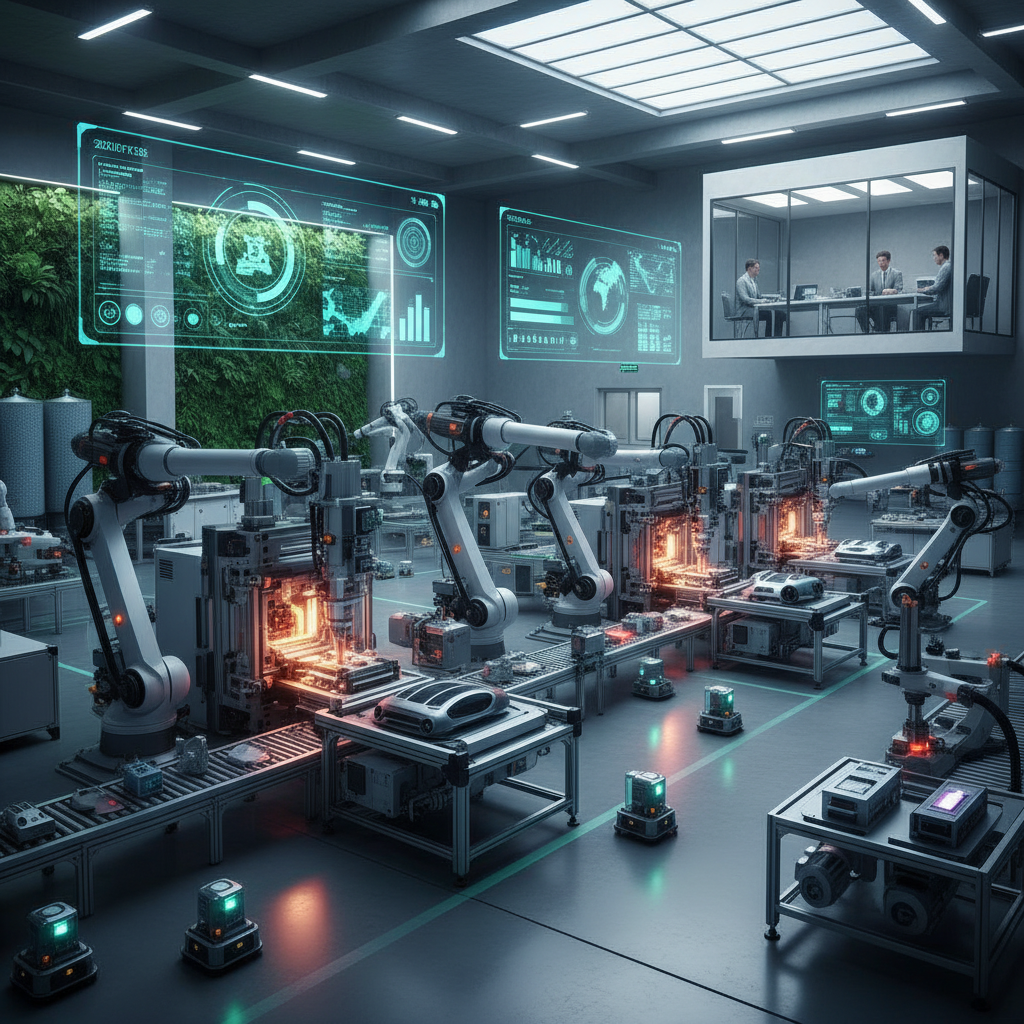

In addition to market expansion, several trends are expected to shape the mold injection landscape. The rise of Industry 4.0 technologies, including automation, IoT integration, and advanced materials, promises to enhance operational efficiency and product quality. For instance, the use of simulation software in mold design is anticipated to reduce lead times and material waste significantly. Furthermore, sustainability concerns are compelling manufacturers to adopt eco-friendly practices and materials, fundamentally altering their approach to mold injection processes. As we delve into the top trends in mold injection manufacturing and market growth insights, focusing on these emerging developments will be crucial for industry stakeholders aiming to remain competitive in this dynamic environment.

Future-Proofing Mold Injection: Innovations Shaping 2025

As the mold injection manufacturing industry evolves, several innovations are expected to shape its landscape by 2025. Advanced technologies such as additive manufacturing and intelligent automation are becoming crucial in enhancing production efficiency and reducing lead times. According to a recent report by MarketsandMarkets, the global injection molding market is projected to grow from $221 billion in 2020 to $325 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.2%. This growth is directly tied to the industry's ability to adopt new technologies that streamline operations and improve precision.

One key trend is the rise of sustainable practices within mold injection manufacturing. Companies are increasingly integrating eco-friendly materials and energy-efficient processes into their operations. The demand for biodegradable plastics, for instance, has surged, aligning with environmental regulations and consumer preferences. The Frost & Sullivan report indicates that the sustainable packaging market, which heavily relies on mold injection, is estimated to reach $250 billion by 2024.

**Tips: Embrace Technology**: To future-proof your business, consider investing in Industry 4.0 technologies. Implementing smart sensors and IoT solutions can help monitor production in real-time, leading to significant cost savings.

**Tip: Focus on Sustainability**: Shift towards using sustainable materials and processes. This not only meets regulatory demands but also attracts eco-conscious customers, fostering brand loyalty and enhancing your market reputation.

2025 Top Trends in Mold Injection Manufacturing and Market Growth Insights

| Trend | Description | Market Impact | Projected Growth (%) | Key Technologies |

|---|---|---|---|---|

| Sustainability Initiatives | Integration of eco-friendly materials in mold manufacturing. | Positive effect on brand reputation and compliance with regulations. | 15% | Biodegradable Polymers |

| Industry 4.0 Technologies | Implementation of IoT and automation in production lines. | Increased efficiency and reduced operational costs. | 20% | Smart Sensors, AI |

| Advanced Materials | Use of high-performance thermoplastics and composites. | Higher product durability and performance. | 10% | Carbon Fiber, PEEK |

| 3D Printing Integration | Creating molds using additive manufacturing for rapid prototyping. | Reduced lead time and costs for mold creation. | 25% | SLA, FDM technologies |

| Data-Driven Decision Making | Utilizing big data analytics to optimize molds and reduce waste. | Enhanced productivity and decision efficiency. | 15% | Predictive Analytics Tools |

Sustainability Trends: Eco-Friendly Materials in Mold Production

The landscape of mold injection manufacturing is increasingly influenced by sustainability trends, particularly the rise of eco-friendly materials in mold production. As industries face mounting pressure to reduce their environmental footprint, manufacturers are turning to biodegradable and recycled materials that not only meet performance standards but also promote a circular economy. This shift is prompted by consumer demand for greener products and stringent regulations aimed at reducing plastic waste.

Innovative materials such as bioplastics and composite materials derived from renewable sources are now being integrated into the mold production process. These advancements enable manufacturers to create high-quality molds capable of producing sustainable products. Moreover, the use of eco-friendly materials often leads to reduced energy consumption during the manufacturing process. Companies are investing in research and development to improve the properties of these materials, making them more competitive with traditional options. This trend not only fosters environmental stewardship but also opens new avenues for market growth, ultimately aligning profit with purpose in the mold injection industry.

Automation and AI: Enhancing Efficiency in Injection Manufacturing

In the ever-evolving landscape of mold injection manufacturing, the integration of automation and artificial intelligence (AI) is emerging as a transformative force. These technologies not only streamline production processes but also enhance precision and reduce waste. Automated systems can manage repetitive tasks with remarkable efficiency, freeing up human operators to focus on more complex problem-solving activities.

AI algorithms analyze vast amounts of data, allowing for predictive maintenance and optimization of machine performance, ultimately leading to cost savings and higher output quality.

Tips for Implementation: When considering automation, start with a clear assessment of your current workflow. Identify bottlenecks and areas where repetitive tasks can be automated. Additionally, invest in training your workforce to work alongside new technologies, ensuring a smooth transition that maximizes both efficiency and employee satisfaction.

As the industry continues to prioritize speed and agility, the role of AI will expand. From machine learning-driven design improvements to real-time quality control, AI's capabilities will redefine how mold injection manufacturing operates. The anticipated rise in market growth is closely tied to companies willing to embrace these innovations, ensuring they remain competitive in this fast-paced environment.

Tips for AI Integration: Focus on small-scale pilot projects to evaluate the effectiveness of AI applications. This allows for adjustments based on real-world performance, minimizing risk while optimizing the production line for better outcomes.

Market Dynamics: Key Drivers of Growth in the Injection Molding Sector

The injection molding sector is experiencing dynamic growth, driven by several key factors that are reshaping the market landscape. One of the primary drivers is the increasing demand for miniaturized components, particularly in the medical device industry. As healthcare continues to evolve towards more compact and precise solutions, the thermoplastic micro molding market is witnessing significant expansion. This trend highlights the industry's need for high-quality, small-scale manufacturing processes capable of delivering intricate designs.

Another crucial aspect influencing market dynamics is the rise in bioplastics, such as bio-polypropylene. This segment is projected to see substantial growth, with forecasts suggesting a market value of USD 1,160.28 million by 2029. This shift towards sustainability is not only responding to environmental concerns but also enhancing the competitive edge of companies that adapt to the evolving preferences for eco-friendly materials. The integration of innovative technologies and materials is therefore pivotal, positioning businesses to capitalize on the burgeoning demand and ensure sustainable practices within the injection molding market.

2025 Trends in Mold Injection Manufacturing

Competitive Landscape: Evaluating Major Players and Emerging Startups in 2025

The competitive landscape in mold injection manufacturing is rapidly evolving as we approach 2025, driven by both established leaders and emerging startups. Major players continue to invest heavily in automation and smart manufacturing technologies, which are projected to enhance production efficiency by up to 30%. These advancements not only optimize operational workflows but also reduce waste, aligning with the industry’s increasing focus on sustainability.

Emerging startups are carving out their niche by introducing innovative materials and eco-friendly production methods. Reports indicate that the market for sustainable mold injection solutions is anticipated to grow at a CAGR of 20% between 2025 and 2035, highlighting a significant shift towards environmentally responsible practices. This influx of new entrants fosters competition, pushing established firms to adapt and innovate. As both established organizations and newcomers strive to expand their market share, collaboration opportunities are likely to emerge, further driving growth and technological advancements in the industry.

Related Posts

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners

-

Top 10 Benefits of Mold Injection for Effective Product Manufacturing

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products

-

Exploring Innovations in Plastic Manufacturing: Sustainable Solutions for Tomorrow

-

Exploring the Future of Union Tool: Innovations and Applications in Today’s Industry

-

2025 Top Plastic Injection Molded Parts: Innovations and Market Trends