2025 Top 5 Innovative Prototype Molds Transforming Product Development

In the rapidly evolving landscape of product development, the significance of innovative prototype molds cannot be overstated. As the industry embraces advanced technologies and methodologies, these molds are playing a pivotal role in transforming how businesses conceptualize, design, and produce their products. According to Dr. Emily Carter, a leading expert in the field of prototype molds, “The future of product innovation lies in our ability to leverage advanced molding techniques, which not only streamline the development process but also enhance creativity and precision.”

As we look ahead to 2025, a select group of innovative prototype molds is set to redefine the standards of product development across various industries. These cutting-edge solutions not only reduce time-to-market but also allow for greater flexibility in design iterations, enabling companies to respond swiftly to market demands. With rising consumer expectations and the tremendous pressure to innovate, harnessing the potential of these molds is becoming increasingly essential for success.

In this exploration of the top five innovative prototype molds set to transform product development, we will delve into the technological advancements, industry applications, and the broader implications of these molds on the future of manufacturing. By understanding and adopting these innovations, businesses can ensure they remain competitive in a fast-paced and ever-changing market landscape.

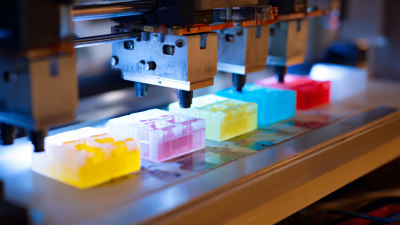

Revolutionary 3D Printing Techniques for Rapid Prototype Mold Creation

In recent years, the landscape of product development has been fundamentally reshaped by revolutionary 3D printing techniques, particularly in the creation of prototype molds. Advanced additive manufacturing technologies have drastically reduced the time and cost associated with traditional mold-making processes. A report by the Wohlers Associates 2021 indicates that the global 3D printing market is expected to grow from $12 billion in 2020 to over $34 billion by 2024, highlighting a shift towards more efficient production methods that cater to customized and small-batch manufacturing.

One of the standout innovations in this field is the use of multi-material 3D printing, which allows for the creation of complex molds that can include varying material properties in a single build. This technique not only accelerates the prototyping phase—reducing it from weeks to mere days—but also enhances the functional testing of designs before moving to full-scale production. Moreover, research from Accenture forecasts that 3D printing could reduce product development costs by up to 70%, enabling companies to experiment more freely with their designs and innovate rapidly while minimizing risk. With such compelling advantages, it is clear that innovative prototype molds and the corresponding printing technologies will play a pivotal role in the future of product development.

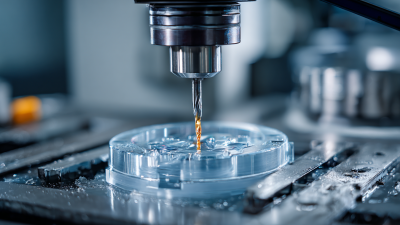

Advanced Materials Driving Innovation in Prototype Mold Design

The advancement of materials technology is revolutionizing prototype mold design, pushing the boundaries of what is possible in product development. With new composites and high-performance polymers, designers can create molds that offer greater durability, reduced weight, and enhanced thermal stability. These innovative materials not only improve the longevity of molds but also facilitate the production of complex geometries that were previously unattainable, enabling rapid prototyping and iterative design processes.

In addition to the mechanical advantages, advanced materials are also contributing to sustainability in manufacturing. Biodegradable polymers and recycled composites are becoming prominent in mold-making, significantly reducing the environmental impact of prototype production. As companies focus on eco-friendly practices, these innovative materials align perfectly with modern manufacturing goals, offering a dual benefit of performance and responsibility. The synergy between advanced materials and innovative mold design is setting the stage for more efficient, effective, and sustainable product development strategies in the years to come.

Smart Technologies Enhancing the Efficiency of Mold Production

Advancements in smart technologies are revolutionizing the efficiency of mold production, paving the way for innovative prototype molds that streamline product development processes. By integrating artificial intelligence and machine learning into design and manufacturing, companies can optimize the molding process to reduce waste and improve turnaround times. These intelligent systems can analyze vast amounts of data to predict potential issues and suggest enhancements, allowing teams to make informed decisions quickly.

Additionally, automation is playing a critical role in enhancing productivity in mold production. Automated machinery can perform repetitive tasks with precision and speed, freeing skilled workers to focus on more complex aspects of the design process. Moreover, technologies such as 3D printing enable rapid prototyping, allowing for quicker iterations and adjustments to molds without significant downtime. The use of these smart technologies not only boosts efficiency but also enhances the overall quality of the final product, empowering manufacturers to meet increasing market demands effectively.

Sustainable Practices in Prototype Molding for Eco-Friendly Products

In recent years, the emphasis on sustainability has dramatically influenced various sectors, including product development. Prototype molding has evolved to incorporate eco-friendly practices that not only aim to reduce waste but also enhance the efficiency of the design process. Innovative materials, such as biodegradable plastics and recycled composites, are gaining traction in prototype creation, providing companies with greener alternatives without compromising quality or functionality. This shift not only aligns with consumer preferences towards sustainability but also helps manufacturers meet stricter environmental regulations.

Moreover, the adoption of advanced molding technologies, such as 3D printing and additive manufacturing, plays a pivotal role in minimizing material waste during the prototyping phase. These techniques allow for precise control over the amount of material used, enabling designers to create prototypes that are both efficient and sustainable. As companies increasingly focus on sustainability, they are also investing in practices like energy-efficient machinery and closed-loop systems, which further reduce their environmental footprint. Such transformations in prototype molding are essential for developing eco-friendly products that resonate with today’s environmentally conscious consumers.

Integration of AI and Machine Learning in Prototype Development Processes

The integration of AI and machine learning in prototype development is revolutionizing the way products are designed and produced. By leveraging these advanced technologies, companies can analyze vast amounts of data to predict potential design flaws and optimize materials before a prototype is even created. This proactive approach not only reduces production costs but also accelerates the overall development cycle, enabling businesses to bring their innovative ideas to market more quickly.

Tips: To maximize the benefits of AI and machine learning in your prototype development, consider implementing simulation tools that can model different scenarios and outcomes. This can help you identify the most effective designs early in the process. Also, collaborate with data scientists to ensure that you are harnessing the full potential of the data you collect, allowing for more informed decision-making.

Moreover, machine learning algorithms can automate repetitive tasks involved in prototyping, freeing up human resources to focus on creative and strategic aspects of product development. As companies continue to adopt these technologies, the prototype creation process will become more efficient, precise, and aligned with market needs.

Tips: Stay updated on the latest AI tools available in the market. Regular training and scalability options can help your team adapt smoothly to technological advancements, enhancing your development capabilities further.

Related Posts

-

Top 5 Benefits of Using Prototype Plastic Molding for Your Product Development

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners

-

What is Plastic Mold Injection Machine? A Comprehensive Guide to Its Types and Applications

-

The Ultimate Guide to Choosing the Best Union Tool for Your Project

-

Exploring Innovative Molding Solutions: Transforming Ideas into Reality Through Advanced Techniques

-

Understanding the Process: How Injection Molding Molds Shape Our Daily Products