2025 Top Plastic Injection Molded Parts: Innovations and Market Trends

In the rapidly evolving world of manufacturing, plastic injection molded parts have emerged as a cornerstone of modern production methods, reflecting significant advancements in technology and design. As we look towards 2025, the industry is set to witness groundbreaking innovations that will redefine the landscape of plastic components. This article delves into the top five trends that are poised to shape the future of plastic injection molded parts, highlighting the interplay between sustainable practices, enhanced efficiency, and the integration of smart technologies.

With growing environmental concerns, the demand for eco-friendly materials and processes is steering companies toward sustainable options in plastic injection molding. Concurrently, manufacturers are adopting advanced techniques that not only improve the quality of molded parts but also reduce production cycle times. The incorporation of automation and IoT technologies is transforming traditional practices, allowing for smarter manufacturing solutions that cater to an increasingly competitive market.

As we explore the leading innovations and market trends for plastic injection molded parts in 2025, we will also consider how these developments can drive growth and profitability. From material advancements to design flexibility, the future of plastic injection molded parts holds exciting opportunities for businesses aiming to stay ahead in a dynamic industry landscape.

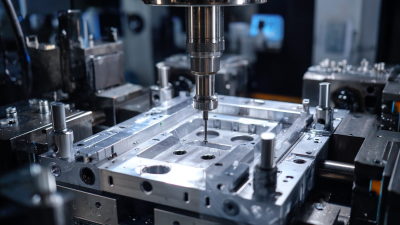

2025 Innovations in Plastic Injection Molding Technology and Techniques

The plastic injection molding industry is poised for significant advancements in 2025, with innovative technologies and techniques set to transform production efficiencies. The global plastic market is expected to grow from $504.31 billion in 2025 to $733.46 billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.50%. This growth underscores the industry's shift towards adopting more sustainable practices and enhancing production processes.

One of the key trends influencing this sector is the expansion of the global injection molding machine market, projected to reach $1.2 billion by 2025, with an anticipated growth to $1.97 billion by 2035, at a CAGR of 5.0%. This increase is attributed to the rising demand for high-performance molds and increased automation in manufacturing processes. Furthermore, the metal injection molding market is set to expand significantly, with a value exceeding $5.15 billion in 2025 and a robust CAGR of over 9.1% projected, driven largely by the escalating gun trade and the need for precision-engineered components. These trends illustrate a dynamic shift within the plastic injection molding landscape, marked by a blend of technological innovation and market expansion.

Emerging Materials for Enhanced Performance in Injection Molded Parts

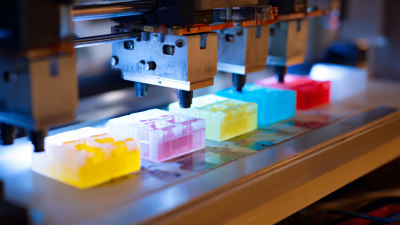

The landscape of plastic injection molded parts is rapidly evolving, driven by emerging materials that promise enhanced performance and efficiency. As manufacturers seek to produce components that meet the increasing demands for durability and sustainability, innovative materials such as bio-based plastics, high-performance composites, and advanced thermoplastics are gaining traction. These materials not only offer improved mechanical properties but also contribute to reduced environmental impact, aligning with global trends toward greener production practices.

In addition to sustainability, the introduction of smart materials is revolutionizing the capabilities of injection molded parts. These materials can adapt their properties in response to external stimuli, opening new avenues for applications in various industries, from automotive to healthcare. The integration of additives that enhance conductivity, impact resistance, or thermal stability further enhances the functionality of molded parts. As manufacturers invest in research and development to explore these advancements, the future of injection molding will likely focus on leveraging these emerging materials to create parts that meet the intricate needs of a modern market.

Key Market Trends Shaping the Future of Plastic Injection Molding

The plastic injection molding industry is poised for significant transformation as we approach 2025, driven by several key market trends. One of the most notable trends is the projected growth of the global micro injection molding machine market, which is expected to expand from $551.3 million in 2025 to $759.2 million by 2032. This growth indicates a rising demand for precision components across various sectors, including electronics and medical devices, where small and intricate parts are vital.

Additionally, the demand for powder injection molding in the USA is forecasted to reach USD 4.2 billion, with a robust compound annual growth rate (CAGR) of 8.9% during the next decade. This trend highlights a shift towards more efficient applications, enabling manufacturers to produce complex geometries and high-performance materials. As the industry continues to evolve, these trends will not only shape product innovations but also drive advancements in technology and sustainability within plastic injection molding.

2025 Top Plastic Injection Molded Parts: Innovations and Market Trends

| Part Category | Application | Material Type | Market Growth Rate (%) | Innovation Focus |

|---|---|---|---|---|

| Automotive Parts | Interior and exterior components | Polycarbonate | 8.5 | Lightweight materials |

| Medical Devices | Syringes and connectors | Polypropylene | 6.2 | Sterilization processes |

| Consumer Electronics | Casing and components | Acrylonitrile Butadiene Styrene (ABS) | 7.8 | Sustainability and recyclability |

| Packaging | Containers and closures | High-Density Polyethylene (HDPE) | 5.0 | Biodegradable materials |

| Industrial Equipment | Machinery parts and housings | Nylon | 9.0 | Durability enhancements |

Sustainable Practices in Plastic Injection Mold Design and Production

The trend towards sustainable practices in plastic injection mold design and production is gaining momentum amid rising environmental concerns. The global polypropylene market, valued at $85.58 billion in 2023, is projected to reach $89.39 billion by 2024, with a compound annual growth rate (CAGR) of 4.64% through 2031. This growth is largely driven by rapid urbanization and industrialization in emerging economies, necessitating a shift towards eco-friendly manufacturing processes.

Innovations in materials, such as ppsu for micro-hole parts, showcase the industry’s commitment to sustainability. The superior properties of ppsu, including high-temperature resistance and chemical durability, make it suitable for diverse applications, further pushing market growth. Additionally, the global injection molding software market is expected to reach $1.1 billion by 2024, with a robust CAGR of 9.54% through 2033, highlighting the increasing reliance on technology to optimize production efficiency and reduce waste. Companies focusing on sustainable materials and practices are poised to lead the competitive landscape as consumers increasingly favor environmentally responsible products.

Impact of Industry 4.0 on Plastic Injection Molding Processes and Efficiency

The emergence of Industry 4.0 is revolutionizing the

plastic injection molding sector through the integration of smart technologies, automation, and data analytics.

Advanced sensors and IoT-enabled devices are now embedded in machinery, allowing for real-time monitoring and

data collection during the molding process. This connectivity enhances decision-making by providing manufacturers

with unprecedented insights into production efficiency, equipment performance, and potential bottlenecks.

With predictive analytics, companies can

anticipate maintenance needs, thereby minimizing downtime and extending the lifespan of their equipment.

Additionally, automation plays a crucial role in streamlining operations and increasing throughput.

Robotics and automated systems are replacing traditional

manual processes, enabling faster cycle times and more precise mold handling. This shift not only boosts productivity

but also enables a more flexible manufacturing environment, allowing for rapid changes

in production volumes and customization of parts. As manufacturers embrace these technologies, they not only increase

their operational efficiency but also position themselves competitively within the market, making way for innovative designs and enhanced product quality that meet evolving

consumer demands.

Related Posts

-

Revolutionizing Injection Mold Design: Exploring Advanced Techniques and Their Impact on Production Efficiency

-

Top 5 Benefits of Using Prototype Plastic Molding for Your Product Development

-

Demystifying the Injection Moulding Process: A Comprehensive Guide for Beginners

-

Exploring the Future of Union Tool: Innovations and Applications in Today’s Industry

-

How Injection Mold Manufacturing is Revolutionizing Product Development in 2023

-

Transforming Manufacturing Efficiency with Advanced Plastic Injection Machine Technology